What is ERP: Considerations and alternatives

Implementing an Enterprise Resource Planning (ERP) system is a major step for any business. While ERP solutions promise to streamline operations and enhance productivity, the road to successful implementation is complex. From aligning the system with your business needs to ensuring that your team is prepared for the transition, it's crucial to consider key factors to avoid costly missteps.

In this article, we’ll cover all the key factors you need to consider before deciding whether to implement ERP in your business and, if so, how to go about it.

What is ERP?

ERP, which stands for Enterprise Resource Planning, literally means the planning and management of all business resources.

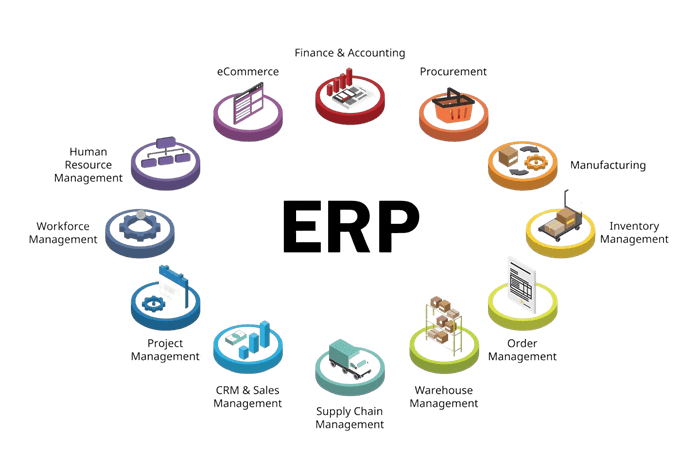

ERP software is an all-in-one technology solution that integrates various applications into modules within a single software package. ERP software aims to create a unified and streamlined data system across departments and functions, such as purchasing, production, and human resource management.

A complete ERP system typically consists of the following modules:

- Finance (Accounting)

- Production planning and control

- Purchase control

- Sales and distribution management

- Project management

- Human resource management

- Service management

- Stock control

- Tax reporting

- Management reporting

Some modern ERP software also includes integrations with devices like mobile phones, barcode scanners, handheld computers, etc., to enhance functionality.

Why is ERP important?

The power of ERP lies in the "unified database", from which business leaders can extract insights from their operations while minimizing risks of data errors.

ERP helps control financial information

Usually, financial data is compiled from different departments, leading to discrepancies. With ERP, all finance-related data is consolidated in one place, ensuring a single, unified version across all departments and locations. When a number changes, all related information is automatically recalculated and updated to ensure consistency, reducing the risk of financial errors.

Thanks to ERP, large and complex companies no longer need to wait until the end of the month or quarter to compile data. Whenever management needs an accurate, up-to-date financial report, they can simply check the live data in the ERP system.

ERP reduces errors when multiple people handle the same data

In reality, businesses often face data mistakes as information passes through different departments. For example, handwritten “14” boxes can easily be mistaken for “19,” or a typo may turn customer “Micheal” into “Michelle.” Such errors slow down the workflow, harm the company’s image, reduce transparency, and cause internal friction among employees.

With ERP, data only needs to be entered once by the first person, and it’s stored intact in the system. Any employee accessing the data will see the original version, not a “third-hand copy.”

ERP makes it easier to monitor employee workflows

A centralized database with standardized business processes makes it easier for companies to implement internal controls. ERP software allows you to quickly trace the origin of any transaction and identify which employees were involved.

Managers can stay in one place, open the unified ERP interface, and instantly view the results of all employees’ work, even down to the smallest details—such as which products were sold this morning and how much revenue was generated.

Some ERP systems also have automatic data analysis features that assign tasks to employees based on their strengths, saving managers time in task delegation.

ERP creates an internal social network for the company

ERP software often integrates internal communication features for users within the system. This can include private chats or status updates, functioning similarly to an internal social network for the company.

Signs that you possibly need an ERP system

A business should consider implementing ERP software if it finds itself in one of the following three situations:

- Having frequent errors in data transfer and coordination across departments, such as issues with shipping, invoice mismatches, or inaccurate inventory tracking. ERP ensures real-time updates and unified data flow, improving accuracy and customer satisfaction.

For example, a sales representative confirms an order for 20 items, but the warehouse only has 10 in stock. This forces the rep to go back to the customer and reissue the invoice, wasting time and damaging trust. With ERP, real-time updates ensure sales reps have accurate inventory data, improving service quality and decision-making.

- Are experiencing rapid growth in transactions. When the company’s products and operations expand beyond its management capabilities, it leads to fragmented and scattered information. ERP helps centralize and streamline departmental functions for better oversight and control.

For example: A small food production company expands rapidly after two years, requiring it to split functions like inventory, accounting, and marketing into separate departments. ERP modules help centralize this information, making it easier to manage across all departments.

- Are operating with low efficiency and cumbersome management systems, where manual processes and downtime create hidden costs.

For example, in manual order processing, creating, submitting, and approving orders takes time, while ERP automates these tasks and generates detailed reports. This helps the company identify inefficiencies and optimize its workflow.

How much does ERP cost?

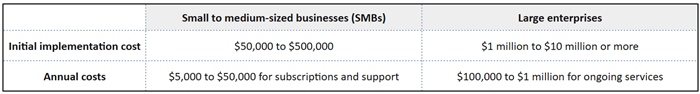

The cost of implementing an Enterprise Resource Planning (ERP) system can vary widely, typically ranging from $50,000 to several million dollars. The total investment depends on numerous factors, including the size of your organization, the complexity of your processes, the specific ERP solution chosen, and the extent of customization and integration required.

Key factors influencing ERP costs

1. Software licensing fees

- On-premises ERP: Requires purchasing licenses upfront, which can be a significant initial expense.

- Cloud-based ERP (Software-as-a-Service): Involves a subscription model with recurring monthly or annual fees, which can be more manageable.

2. Implementation and consulting services

- Planning and project management: Costs for consultants and project managers to oversee the implementation.

- Customization and configuration: Adjusting the ERP system to fit your specific business processes can add to the cost.

- Integration: Connecting the ERP system with existing software (e.g., CRM, HR systems) may require additional investment.

3. Hardware and infrastructure

- For on-premises systems: Servers, networking equipment, and other hardware expenses.

- For cloud systems: Reduced hardware costs but may involve expenses for high-speed internet and security measures.

4. Data migration

Data cleaning and transfer: The process of moving data from old systems to the new ERP can be time-consuming and costly, especially if data quality is poor.

5. Training and change management

- User training: Educating employees on how to use the new system effectively.

- Change management programs: Initiatives to help staff adapt to new processes and workflows.

6. Maintenance and support

- Ongoing support fees: Costs for technical support from the vendor or third-party providers.

- Upgrades and updates: Future expenses to keep the system up-to-date with the latest features and security patches.

7. Additional modules and features

Modules for specialized needs like advanced analytics, supply chain management, or international operations can increase costs.

Estimated cost ranges

Ways to optimize ERP costs

- Thorough planning: Clearly define your requirements to avoid scope creep and unnecessary features.

- Choosing the suitable deployment model: Consider cloud-based solutions to reduce upfront hardware and infrastructure costs.

- Limit customization: Stick to standard functionalities where possible to minimize customization expenses.

- Vendor negotiation: Negotiate terms and prices with vendors; consider multiple quotes to get the best deal.

- Phased implementation: Roll out the ERP system in stages to spread out costs and reduce risk.

- Invest in training: Proper training can improve user adoption and reduce the need for extensive support.

How long does it take to implement ERP?

The time required to implement an Enterprise Resource Planning (ERP) system can vary significantly, typically ranging from a few months to several years. The duration depends on several factors:

- Size and complexity of the organization: Larger organizations with multiple departments, locations, or complex processes will generally require more time to implement an ERP system.

- Scope of implementation: Implementing only core modules (like finance and inventory) is quicker than a full-scale implementation that includes additional modules such as human resources, customer relationship management, and supply chain management.

- Customization needs: Off-the-shelf ERP solutions with minimal customization can be deployed faster. However, the implementation will take longer if your business requires significant customization to fit specific processes.

- Data migration: Cleaning, organizing, and transferring existing data into the new system is time-consuming but critical for a successful implementation.

- Resource allocation: The availability of internal and external resources, including project managers, IT staff, and consultants, can impact the timeline.

- User training and adoption: Ensuring that all users are adequately trained and comfortable with the new system can extend the implementation period but is essential for long-term success.

General timeline estimates

- Small to medium-sized businesses (SMBs): 3 to 6 months, as they ypically have fewer users and simpler processes and may opt for cloud-based ERP solutions with standard configurations.

- Large enterprises: 2 to 5 years, as they often Involve complex, multi-site operations and require extensive customization and integration with other systems.

Factors to consider before ERP implementation

Businesses should keep the following points in mind when implementing ERP:

Detailed plan for costs, resources, and time

When implementing an ERP system, businesses need to carefully plan for costs, resources, and time because:

- ERP is costly

As previously discussed and according to Panorama's 2022 ERP Report, the total cost for ERP implementation in a medium-sized business ranges from $150,000 to $750,000. This price covers a full system with all ERP modules included. However, most companies don't require every module, and ERP systems generally don't allow businesses to select specific applications for individual processes.

- ERP is complex

ERP systems can be overwhelming to implement and maintain, requiring skilled IT staff or external consultants to manage.

- ERP implementation takes time

A lengthy implementation process could make the system outdated by the time it's fully deployed, potentially misaligning with the company's current needs. Moreover, extended implementation times can lead to downtime and productivity loss during the transition period.

Be aware of potential technical risks

While ERP improves accuracy and helps optimize business processes, it also comes with significant technical risks. For example, if a problem arises in one step, it can bottleneck the entire process and delay subsequent operations.

In an ERP system, all modules—such as finance, production planning, purchasing, sales, and project management—use the same data stream. This means that a slight change in one area impacts the entire system, and a minor process error could escalate into a larger issue when handled through ERP.

Prepare for future ERP upgrades and changes

Once implemented, ERPs can be difficult to change or scale for some reasons:

- Changing an ERP post-implementation is costly, often nearly as expensive as implementing a new system.

- Inadequate research into changes can lead to conflicts within the ERP structure, causing errors or even system shutdowns.

- Post-launch changes disrupt workflows, as the system would need to be temporarily taken offline.

Poor customization or implementation can lead to a system that does not fully meet the company’s needs, resulting in underutilization and a wasted investment. Therefore, businesses must carefully evaluate whether an ERP system is the right fit for their operation system and long-term goals.

Which types of business are suitable for ERP?

Considering the abovementioned factors, only certain types of businesses are well-suited for ERP implementation.

- Large enterprises – Companies with multiple departments or subsidiaries spread across different locations need a centralized system to manage their complex operations. The initial investment cost is within budget, comparing to the benefits that ERP can bring.

- Manufacturing companies – Manufacturers often deal with intricate production processes, inventory management, and supply chain coordination. An ERP system can automate and integrate these functions, even if the system is complex and expensive to implement.

- Growing mid-sized companies – Businesses experiencing rapid growth and expanding operations can justify the investment in an ERP system, as it helps manage increasing transaction volumes and diverse operations more efficiently, despite the initial cost and training required.

- Industries with compliance and reporting requirements – Businesses in industries such as healthcare, finance, or pharmaceuticals often have stringent regulatory requirements. An ERP system can centralize data and automate reporting, making it easier to maintain compliance, even if the system may be difficult to modify later.

Combining ERP with Rework.com

While ERP systems excel in providing a unified source of truth and automating transactional processes, they often fail to meet the dynamic communication and collaboration needs of modern businesses. That's why they are referred to as systems of record, focusing mostly on centralizing and managing critical business data such as finance, inventory, and supply chain operations.

This is where ERP systems fall short—they are not designed as systems of engagement. Real-time collaboration, cross-functional communication, and task management are often left unsupported, leading to silos, bottlenecks, and inefficient internal processes.

By combining ERP with Rework.com, businesses can bridge this gap and create a more well-rounded solution that addresses both data management and internal collaboration.

Here’s why this combination is crucial:

Flexibility and scalability

ERP systems are often rigid and difficult to adapt as businesses evolve. Rework, however, offers the flexibility needed to customize workflows and processes as companies grow. Each aspect of your operation on Rework comes with customization and permission settings for you to design, and it requires no coding experience. You can always create-execute-monitor-adjust on the go, which is especially useful for businesses undergoing rapid changes or entering new markets.

Enhanced internal collaboration

ERP systems do not provide tools for real-time team collaboration, leaving teams to rely on external platforms, which can cause inefficiencies. Rework functions as a system of engagement, where employees can communicate, share updates, collaborate on tasks, and track progress all in one place. This real-time interaction ensures smoother workflows and better coordination across departments, closing the gap that ERP systems often leave open.

Always communicate with context - Centralize all discussion related to projects, decisions or processes

Always communicate with context - Centralize all discussion related to projects, decisions or processes

Tailored for small to medium-sized teams

Rework is particularly ideal for smaller teams in both terms of investment cost and user-friendliness. You can always enhance your collaboration efforts without the heavy administrative burden of a full-scale ERP.

ERP x Rework.com: Some use cases

Use-case 1: Purchase requests for additional materials

ERP systems typically have fixed approval flows for large, routine purchase orders. However, smaller, ad-hoc requests, like additional materials or protective gear, can get delayed by unnecessary approval steps.

For urgent or low-value purchases, businesses can use Rework Requests alongside their ERP. This app streamlines the process by:

- Simplifying request creation with details like material, quantity, cost, and approver.

- Instantly notifying the approver, allowing one-click approvals.

- Organizing approval data for easy reporting and auditing.

Use-case 2: Purchasing process tracking

ERP systems typically only capture the final supplier interaction during the purchase request phase, leaving out earlier steps like workload measurement, order tracking, supplier search, and negotiations, which require flexibility.

For more adaptable workflows, businesses can use Rework Flows to complement their ERP.

Final thoughts

ERP is a powerful system and remains a top choice for solving business challenges. However, like any system, ERP has its imperfections. Businesses must be prepared with solutions to overcome these limitations to ensure smooth operations and achieve the highest efficiency. I hope this article has provided useful insights into ERP systems for you and your business, and that you can consider other options that add to the ERP values.

FAQ Section

Frequently Asked Questions about ERP

Tara Minh

Operation Enthusiast

On this page

- What is ERP?

- Why is ERP important?

- Signs that you possibly need an ERP system

- How much does ERP cost?

- Key factors influencing ERP costs

- Estimated cost ranges

- Ways to optimize ERP costs

- How long does it take to implement ERP?

- Factors to consider before ERP implementation

- Which types of business are suitable for ERP?

- Combining ERP with Rework.com

- ERP x Rework.com: Some use cases

- Use-case 1: Purchase requests for additional materials

- Use-case 2: Purchasing process tracking

- Final thoughts

- FAQ Section