Process Management

Transforming your Make-to-Order business: How Rework accelerates operation for growth

Unlike mass production models, Make-to-order (MTO) businesses are distinct in their focus on producing customized products tailored to each customer's specifications. This uniqueness presents specific challenges, such as ever-changing customer requirements, complex production planning, and tight lead times.

As we review multiple MTO businesses, it becomes clear to us that they require a flexible approach to managing resources and a smooth collaboration across sales and production teams, which is infeasible while managed manually. In this article, we’ll explore how Rework.com offers tailored solutions to meet these challenges and accelerate MTO operations for greater profitability.

What is MTO Business? Example

Make-to-order (MTO) businesses focus on producing goods based on individual customer orders, offering a high degree of customization. In contrast to mass production, MTO companies only begin production once an order is placed.

MTO is one of the pull-manufacturing strategies, which means production is based on actual demand, in contrast to push-manufacturing strategies, where production schedule and quantity are determined by forecast.

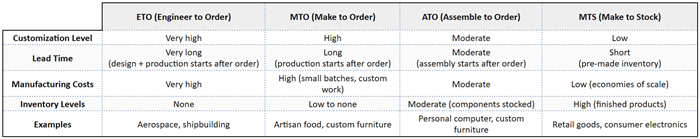

The key difference between MTO and other production models lies in the customization level. Let's dig deeper in the comparison table below:

For the purpose of this article, we’ll focus on simple MTO businesses such as custom food producers, custom artwork, and custom furniture makers. These businesses, while offering customization, do not require the extensive design and engineering phases typical of ETO. Let’s look deeper into what challenges MTO businesses have to face and how Rework.com can help them optimize operations and maximize profitability.

The organization map and the overview of MTO process

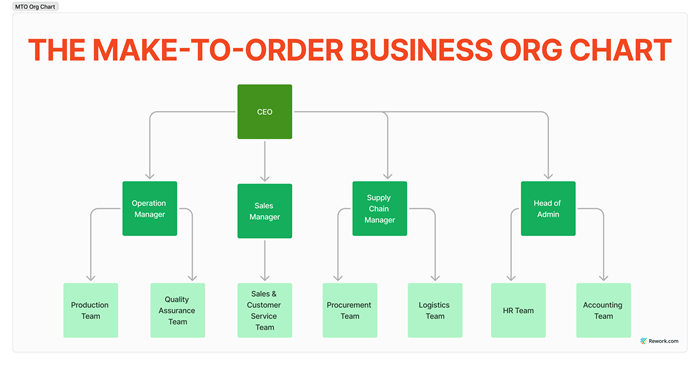

2.1. The organization map

An MTO business generally has these 4 key functions:

- Sales & Customer Service team: This team handles customer inquiries, processes orders, and communicates customization requirements to the production and procurement teams.

- Production/Manufacturing team: This team manages the creation of customized products according to customer specifications. This team coordinates production schedules, allocates resources, and ensures quality control.

- Suply chain team (Procurement & Logisctics): This team is responsible for sourcing and acquiring raw materials or components as soon as the order is confirmed. They must coordinate closely with suppliers to minimize lead time and ensure the timely availability of materials. This team also manages shipping and logistics to deliver the finished goods on time to customers.

- Admin team: This team supports various internal functions such as Human Resources (HR), including hiring, training, payroll, and benefits; and Accounting, including invoicing, payments, and financial reporting.

Depending on the business context, the teams can drill down into more specialized functions or combine into one team. For example, there can be an Operation Manager in charge of Production and Quality Assurance sub-teams; or there will be separate Procurement and Logistics teams.

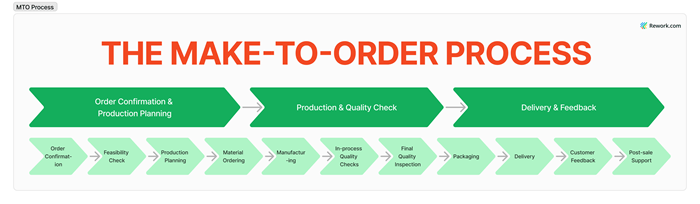

2.2. Overview of the MTO Process:

Let’s break it down into three key stages: Order Confirmation & Production Planning, Production & Quality Check, and Delivery & Feedback, with steps within each.

Order Confirmation & Production Planning

This initial stage sets the foundation for the entire MTO process.

- **Order confirmation:**The customer places an order, specifying product details such as customization, quantity, and delivery date. Sales will collect the order and pass it on to other departments.

- **Feasibility check:**The company assesses the feasibility of the order, including the availability of raw materials, production capacity, and the required lead time. Any necessary adjustments to timelines or costs are discussed with the customer.

- **Production planning:**Once feasibility is confirmed, the production schedule is created. This includes allocating resources (labor, machinery, materials), defining milestones, and setting deadlines for each stage of production.

- **Material ordering:**For customized orders, specific materials or components are ordered. This can involve working with suppliers to ensure timely deliveries based on the production timeline.

Production & Quality Check

Once planning is complete, the focus shifts to the actual production and ensuring the product meets quality standards.

- Manufacturing: The production process starts as per the planned schedule. Depending on the complexity of the order, various sub-processes (e.g., assembly, painting, testing) may occur simultaneously or sequentially.

- **In-process quality checks:

**During manufacturing, quality checks are performed at various stages to ensure the product is being made to the customer's specifications and meets quality standards. - **Final quality inspection:**Once manufacturing is complete, a thorough inspection is carried out.

Delivery & Feedback

After production and quality assurance, the product is ready to be delivered and customer feedback is gathered to refine future processes.

- **Packaging & delivery preparation:**The finished product is prepared for shipping. This includes packaging and preparing all necessary shipping documentation (invoices, warranties, manuals).

- **Delivery:**The product is shipped to the customer, either through in-house delivery teams or third-party logistics providers.

- **Customer feedback:**After delivery, the customer is encouraged to provide feedback on the product and the overall experience. This can involve follow-up calls, surveys, or review requests to assess product satisfaction and identify any areas for improvement.

- **Post-sale Support:**Based on the feedback, any necessary adjustments, troubleshooting, or customer service support is provided.

Are you having these problems managing MTO businesses manually?

Most MTO businesses start small with minimal upfront costs, so they often manage everything manually without any major issues in the beginning. However, as the business grows and they aim to capitalize on their customization strengths, challenges inevitably emerge. We’ve seen many MTO businesses face similar struggles as they scale, including one of our customers, a leading custom cake bakery in the Philippines, which handles several custom cake orders each day and has begun experiencing the limitations of manual processes. Let’s discuss those struggles in more detail:

3.1. Stagnant and disconnected coordination

In many MTO businesses, customers place orders through various channels like Facebook, WhatsApp, or directly with frontline sales staff. These orders are then manually forwarded across departments, leading to a high risk of human error and duplication of work.

A page from a manual form book. Looks familiar?

A page from a manual form book. Looks familiar?

One of our customers shared their experience about how a single order would be recorded and repeated at least four times – once for the accounting team for reporting, then to the dispatch team, then again to the production head, and each sub-production lead. Imagine the frustration of having the same information go through so many hands, creating room for mistakes and wasting time.

On top of that, there will be no synchronicity as the procurement, production, and logistics team relying heavily on emails, phone calls, or manual notes. Without a centralized system, it’s nearly impossible to keep everyone on the same page, which slows everything down.

3.2. Inefficient procurement and inventory management

The procurement process in MTO businesses faces similar challenges. Without a proper digital system, placing orders for materials is often delayed or incorrect, extending lead times and slowing production.

One of our customers shared that they message the procurement team via WhatsApp whenever they get an order, and they already experience issues like duplicate purchasing or mixed-up orders due to the overwhelming number of group chat messages.

3.3. Lack of real-time tracking and visibility

When communication is delayed and scattered, it becomes nearly impossible for managers to keep an eye on the entire operation. Reporting is often delayed, making it difficult to respond proactively to issues.

For example, if a supplier is late or a machine breaks down, the lack of real-time alerts means the issue could go unnoticed until it causes bottlenecks or disrupts delivery schedules. The team simply loses the opportunity to optimize on their efficiency and profits.

_“If you can't measure it, you can't manage it.”

_– W. Edwards Deming.

How Rework can accelerate MTO business

At Rework, the focus is always on understanding the unique challenges each business faces. By collaborating closely with our clients, we help pinpoint areas where improvements are needed, whether it’s in the communication, the data reporting, or simply a lack of human compliance.

To effectively implement technology that solves these problems, we often introduce our SPET (Scope-People-Execution-Technology) formula, first by identifying the problems, the goal and the use case of the software in relation to the business context. By applying this formula, businesses can make sure that technology doesn’t just solve surface-level issues but also becomes an integral part of your business that drives real, measurable improvements.

Now that we have identified the main issues, here are some key strategies MTO businesses should adopt to optimize profits and get ready for growth with the help of Rework:

4.1. Enhancing production efficiency

To solve the throbbing problem of disconnected workflows and miscommunication, Rework offers a simplified and organized production workflow by:

Centralizing customer orders and automating communication: Instead of manually passing orders between teams, Rework allows you to set up a Webform where frontline sales or even customers can enter order details directly. When an order is placed, a job will be automatically generated in the production process of Rework’s Flows and can be easily forwarded to all relevant teams, so that every department is aligned from the start.

Streamlining communication within orders: Any updates, questions, or changes related to an order can be easily tracked and communicated within a job in Rework’s Flows. Team members can comment directly on the job and tag others involved, keeping all communication in one place, so no critical information is lost.

Ensuring timely quality control: In Rework, you can set up reviewers at each stage to make sure the outputs of each stage are up to standard before the job moves to the next stage. You can also set up required tasks for workers to fulfill to make sure certain standards are met.

4.2. Reducing lead time with suppliers

Rework can help reduce procurement delays by:

- Streamlining procurement workflows: Similar to production, the procurement process is easily managed using Rework Flows. The progress of each material order, whether it’s in the payment, delivery, or warehouse loading stage, is visually tracked. The system also centralizes supplier information, eliminating the need for separate supplier management spreadsheets

- Giving real-time visibility to inventory level: With Rework Datasets, you can automatically track inventory levels by integrating them with your procurement and production workflows. It’s now easy for the admin or procurement to give feedback to the production team about the restocking lead time based on the inventory level and decide whether to reorder at a certain point. Automated notifications can also be set up for low stock or reorder points to ensure you never face unexpected shortages.

4.3. Leveraging data for business decisions

By centralizing operations and data, Rework gives managers access to real-time reports, enabling data-driven decisions:

- Ensure compliance: Rework allows businesses to set Service Level Agreements (SLAs), establishing a maximum time allowed for each production stage to ensure timely delivery.

- Track and improve performance: With detailed insights on order fulfillment times, material usage and other data types, managers can take immediate action to optimize processes, identify waste and bottlenecks, and ultimately increase profitability.

4.4. Enhancing customer experience

Optimizing internal processes is just the starting point. By spending less time on manual work, MTO businesses using Rework can now spend more time enhancing customer experience and therefore increasing sales potential by:

- Responsive communication: Rework integrates with Email and Whatspp, allowing prompt notification to customer whenever their order is confirmed or ready for delivery. You can also set up an automatic customer feedback collection process after each order using Rework’s Webforms and Flows to improve service quality and strengthen customer relationships

- Offering premium services: With Rework’s digital order forms, it’s easier to offer modular customization options to customers, increasing the value of each order. Also, by optimizing the production process and ensuring strict compliance, MTO businesses can confidently offer delivery guarantees, making it a key selling point and a competitive advantage.

In summary

While the MTO model allows for flexibility, it also introduces unique challenges when managing manually, such as delayed communication, inefficient procurement, and lack of real-time visibility. These issues can lead to production delays, inefficient workflows and dissatisfied customers.

For small-to-medium MTO businesses struggling with these challenges, Rework provides the ideal solution. If you’re having trouble with misalignment, wasted resources, and prolonged production processes, let’s have a checkup with our business doctor.

Camellia

Content Strategist

On this page

- What is MTO Business? Example

- The organization map and the overview of MTO process

- 2.1. The organization map

- 2.2. Overview of the MTO Process:

- Are you having these problems managing MTO businesses manually?

- 3.1. Stagnant and disconnected coordination

- 3.2. Inefficient procurement and inventory management

- 3.3. Lack of real-time tracking and visibility

- How Rework can accelerate MTO business

- 4.1. Enhancing production efficiency

- 4.2. Reducing lead time with suppliers

- 4.3. Leveraging data for business decisions

- 4.4. Enhancing customer experience

- In summary