Designing an effective order handling process

Video Version: Watch on YouTube

In this session, we’ll explore how to build a streamlined, automated workflow from order intake to fulfillment and show a live demo of how it works inside Rework Flow.

You’ll learn how to:

- Automate task assignments and deadlines

- Centralize order, inventory, and shipping data

- Keep customers updated in real time

- Improve coordination between sales, ops, and logistics teams

Hello everyone. I'm really excited to be here with you today for a session on designing an effective order handling process.

I'm Irene and I'm a part of the customer success team at Rework. So, um, yeah, I have my glass of water here with me already. I hope you have one by your side, too. And let's get ready, shall we?

Where do we begin? Let's start with something that's often overlooked, but absolutely crucial, right? Every single order your business receives is a moment of truth. It's not just a transaction, it's a commitment. And how you handle that commitment—whether you deliver on time, with accuracy, or with the right quality—directly impacts how your customer perceives you.

At Rework, we've seen this again and again. Businesses invest in sales, marketing, and operations, but sometimes underestimate the actual order handling process—where all of those efforts meet reality. That's why we're here today. Because we believe every successful order contributes to your long-term success.

With the help of a technology provider like Rework, we want to help you design a process that isn’t just functional, but scalable, reliable, and customer-friendly.

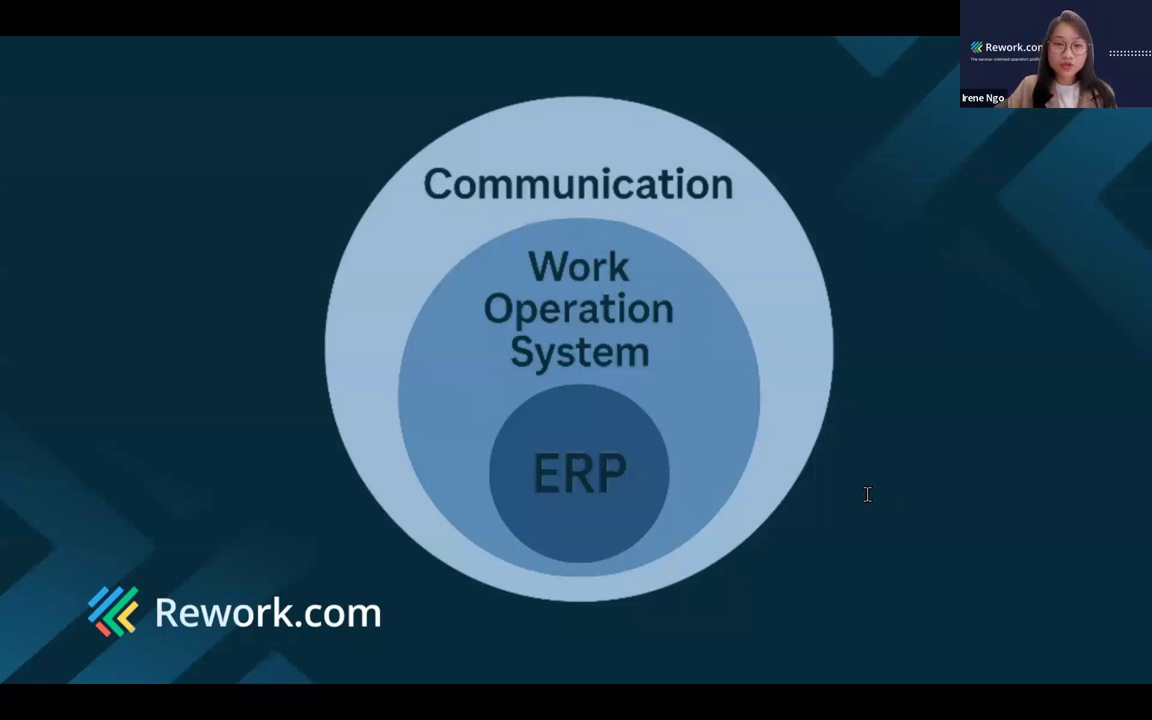

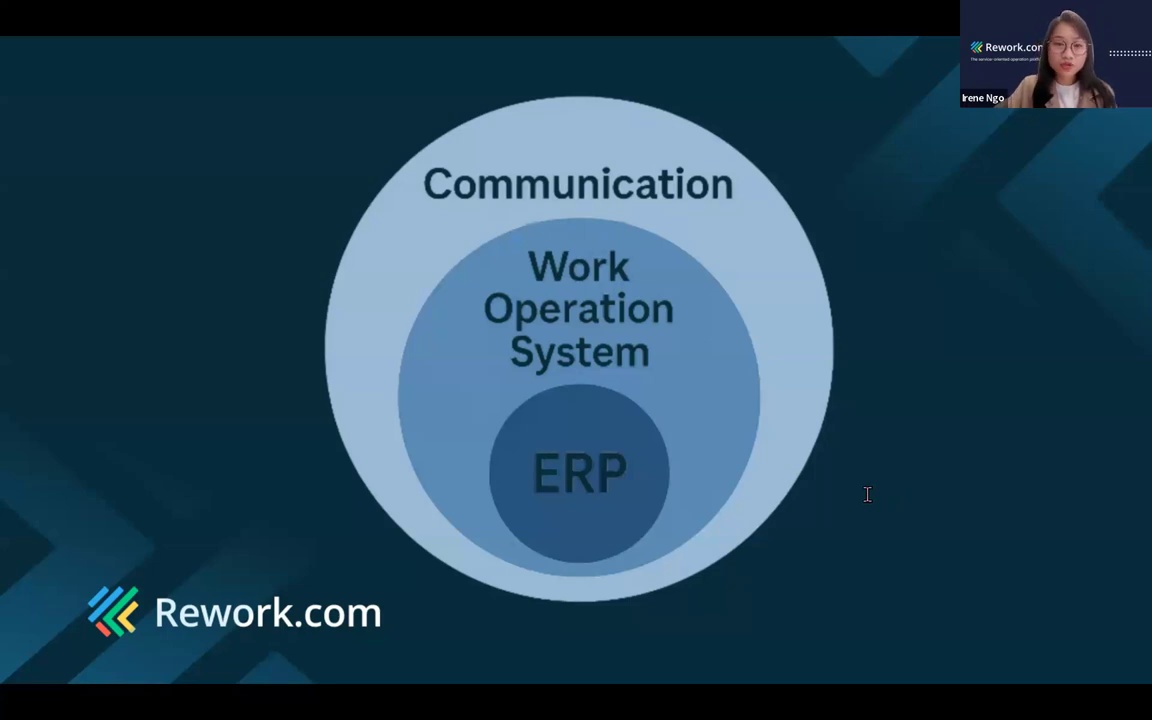

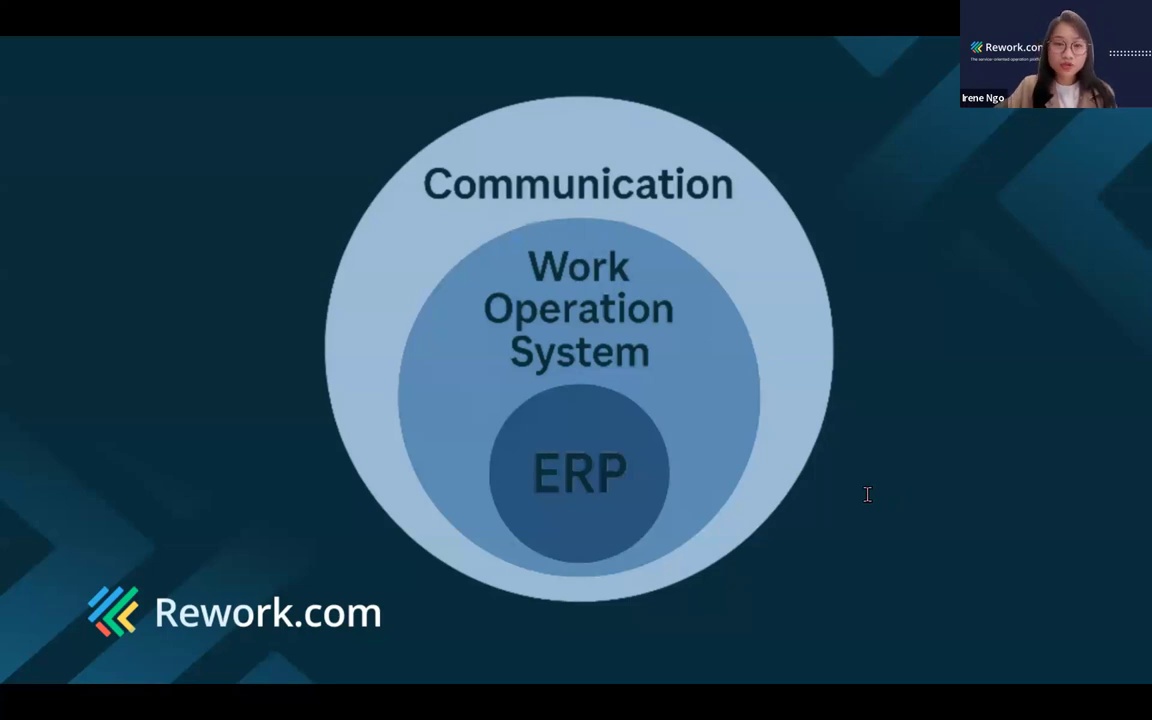

Before we jump in, I want to clarify one thing: order handling touches many parts of a business—quotation generation, warehouse inventory planning—which are often handled by an ERP system.

While those are part of the big picture, today we focus on designing the workflow around the order handling process—how teams collaborate across departments, how handoffs are tracked, how exceptions are handled, and how Rework helps bring structure and visibility to it.

Rework doesn't replace your ERP. Instead, it implements and enforces the process. Think of Rework like a team captain making sure the game plan actually happens on the field—not just on paper.

Here's how we’ll use our time today: we'll break down what a good order handling process looks like, explore common pitfalls, walk through best practices you can apply right away, and do a live demo on our system. And of course, Q&A at the end. Feel free to drop questions in the chat anytime.

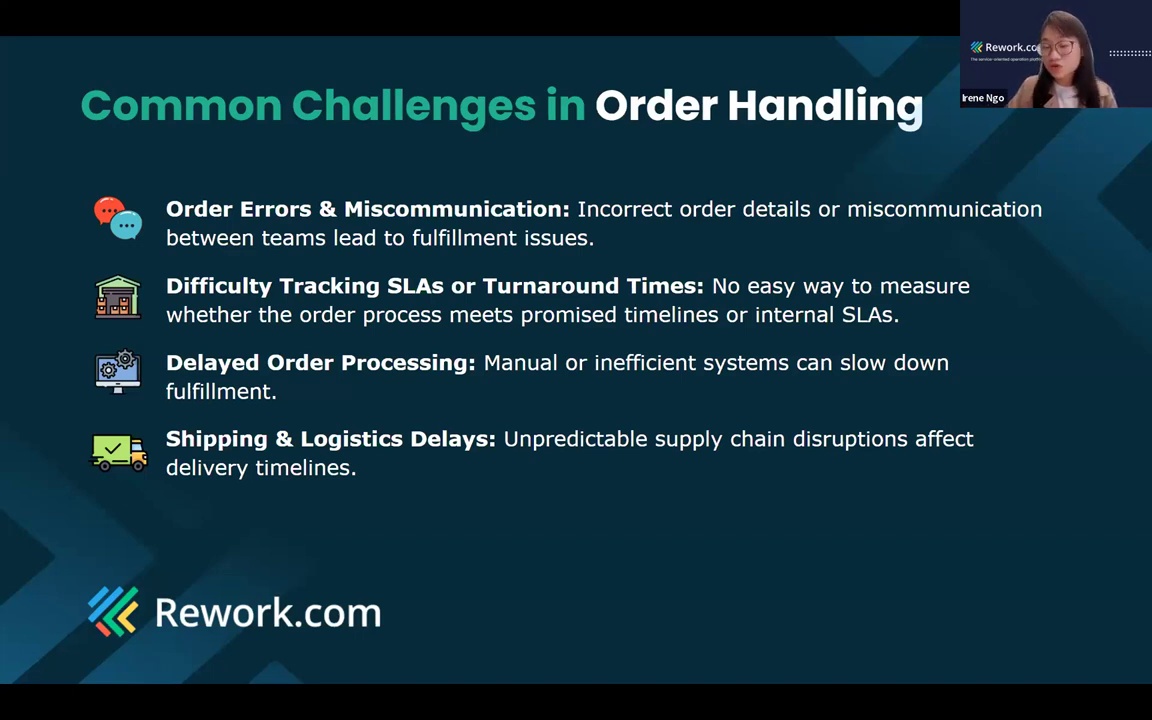

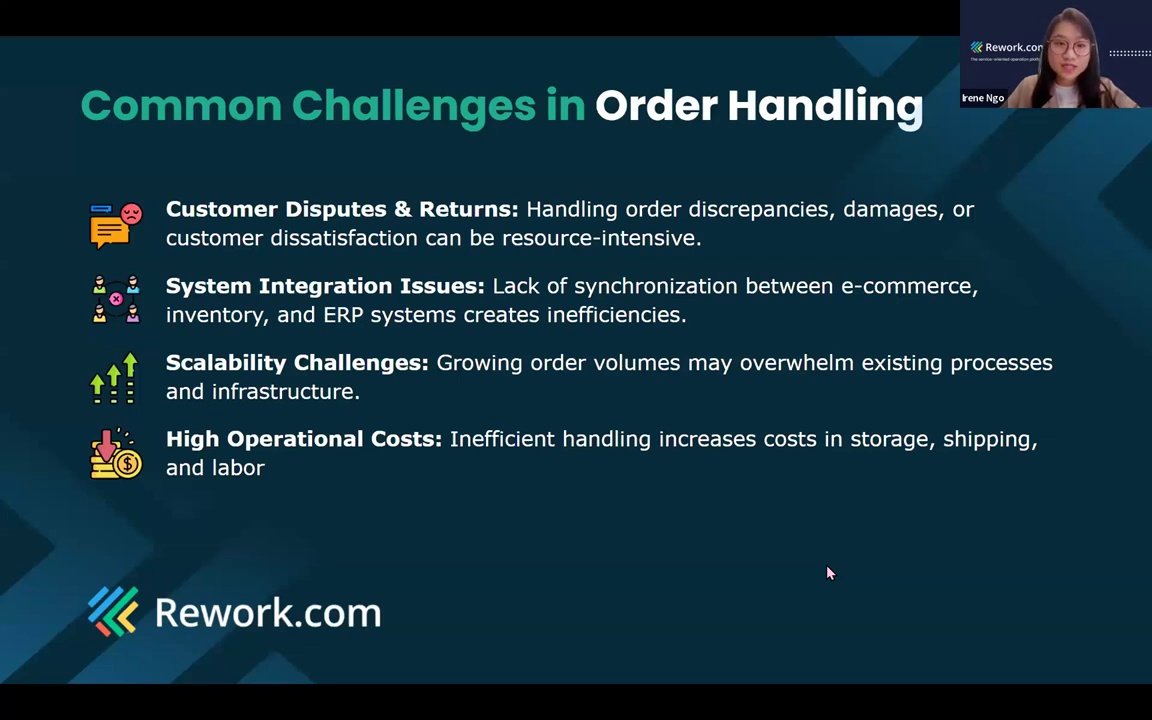

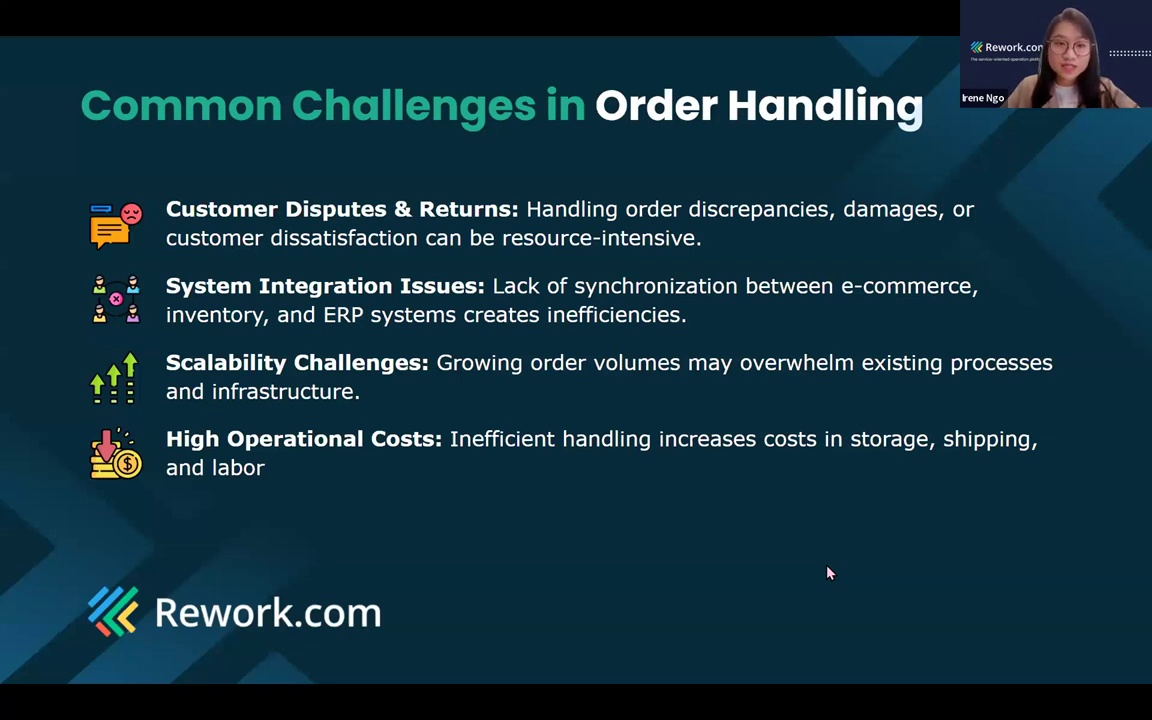

So let’s get into the first part—common challenges in order handling. First, we see operational challenges like order errors. For example, a customer orders three items but someone inputs five. Simple manual mistakes like this happen.

Next is difficulty tracking turnaround times, or what we call SLAs. Then comes delayed order processing or shipping. And beyond that, there are broader issues—customers upset with delays, system integration challenges, or high operational costs.

These are the common problems we see: miscommunication, delays, and lack of visibility. So the question becomes—how do we fix this?

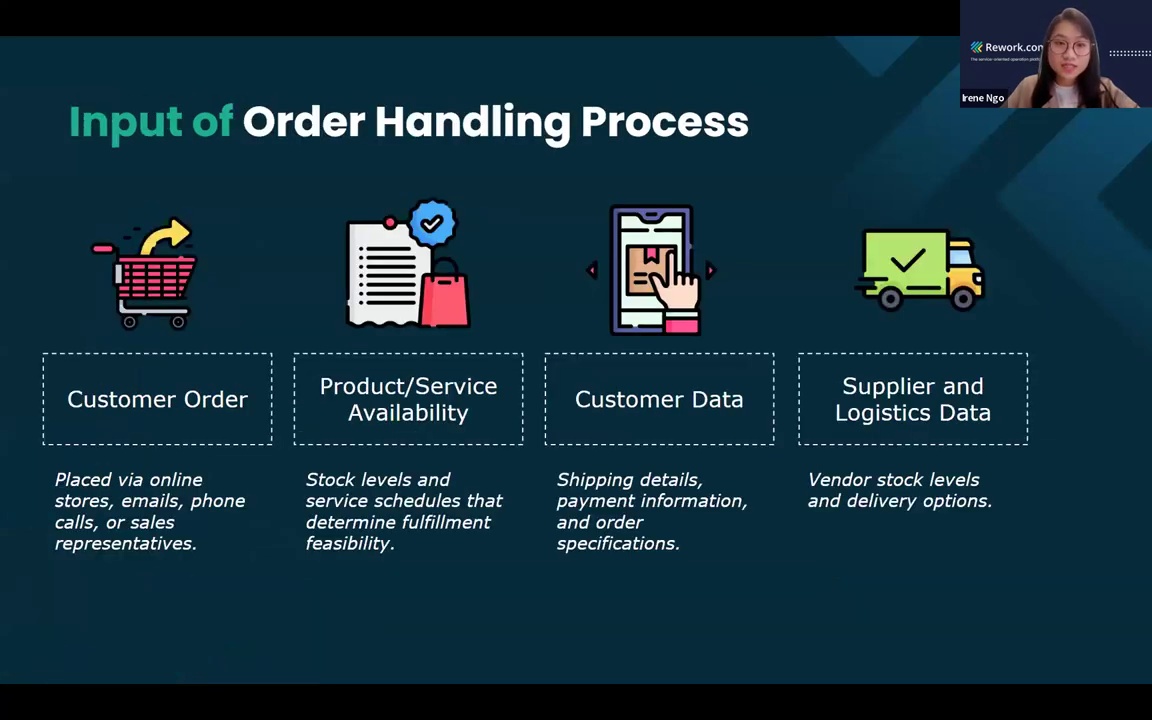

It starts with the input. The input could be anything—a signal that kicks off the order process. It differs by business, but once the order comes in, the clock starts ticking and expectations are set.

This is why input clarity is critical. If you start with incomplete orders, unclear requests, or missing documents, you're already behind.

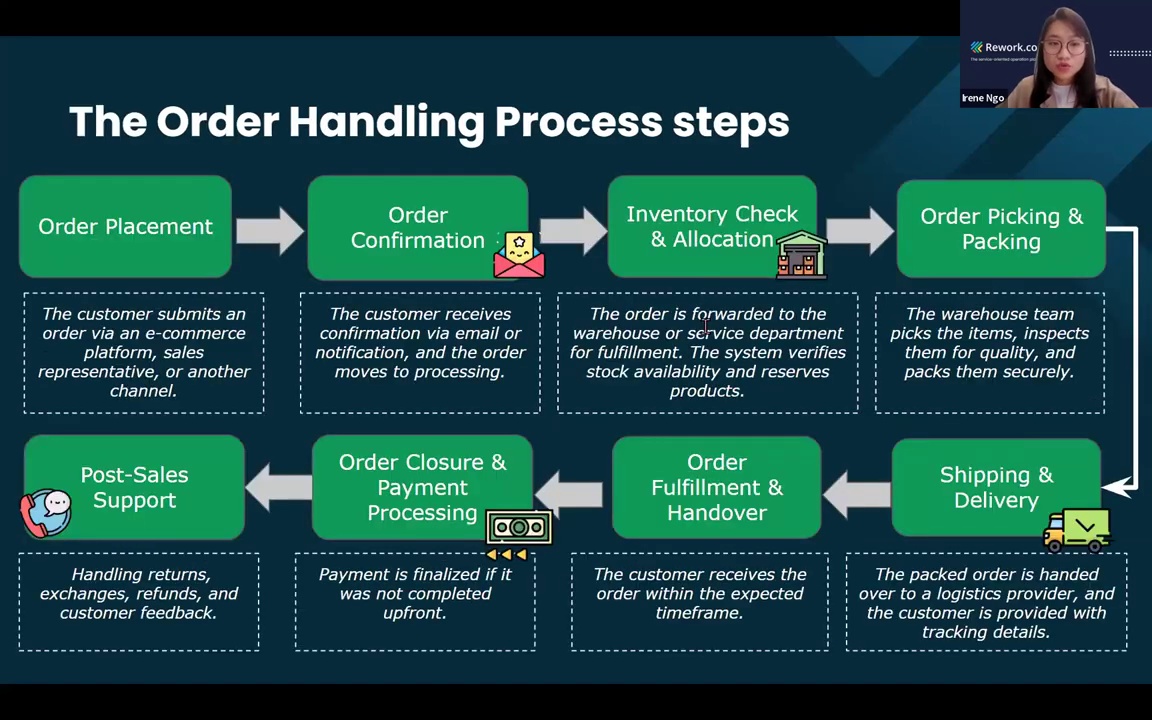

After the input comes the process. This is where the magic or the chaos can happen. This includes verifying the order, checking stock, picking and packing, generating delivery notes, coordinating with third-party logistics, and dispatching.

Sometimes this process is linear, but often it’s not. There are approvals, handoffs, and exceptions. If any step is slow, skipped, or unclear, the whole customer experience is affected.

You could have the best sales team and most loyal customers, but if the order handling process isn't right, then you start to lose trust quietly. So the goal is simple: create a process that is visible and dependable, regardless of who is working on it.

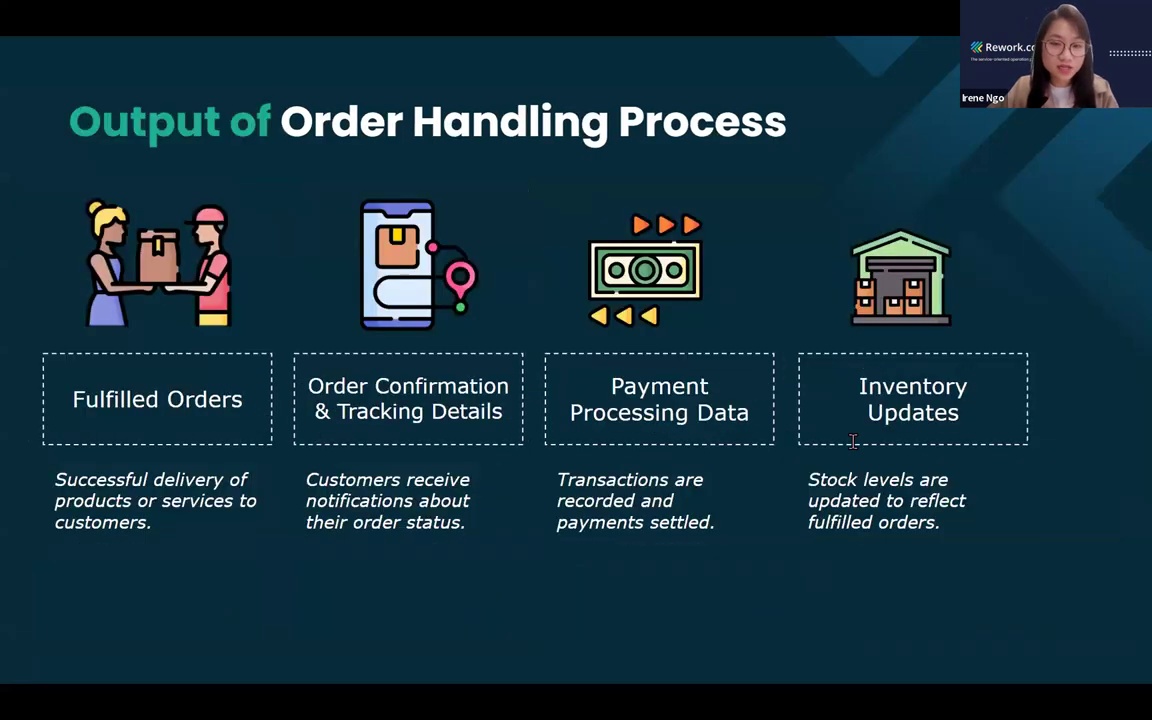

Then we get to the output. The goal isn't just a shipped product, it's an order delivered on time, in full, with care. When done consistently, it builds trust and confidence for both customers and your internal team.

But the opposite is also true. Late or incomplete deliveries, or unclear communication, degrade trust. These issues don’t show up immediately in your financial reports, but they will eventually.

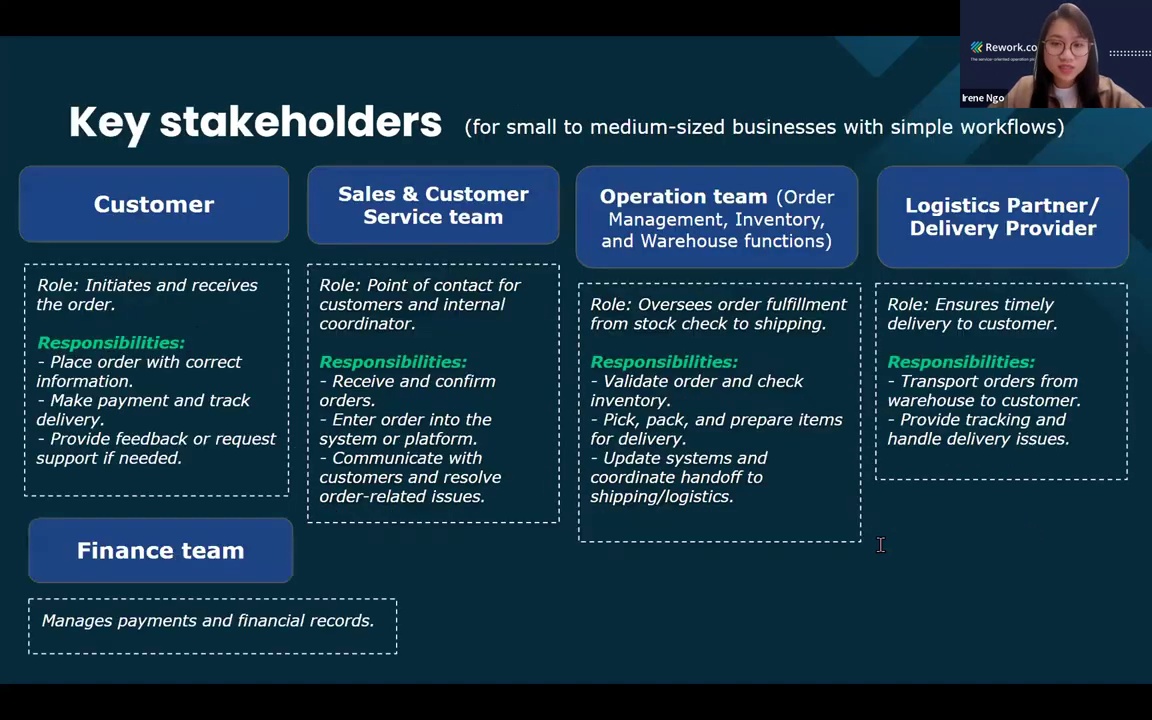

So we've looked at input, process, and output. The next question is: who’s involved in all this? Order handling isn’t just operations—it’s cross-functional. Sales, customer service, operations, warehouse, logistics, finance—all play a part.

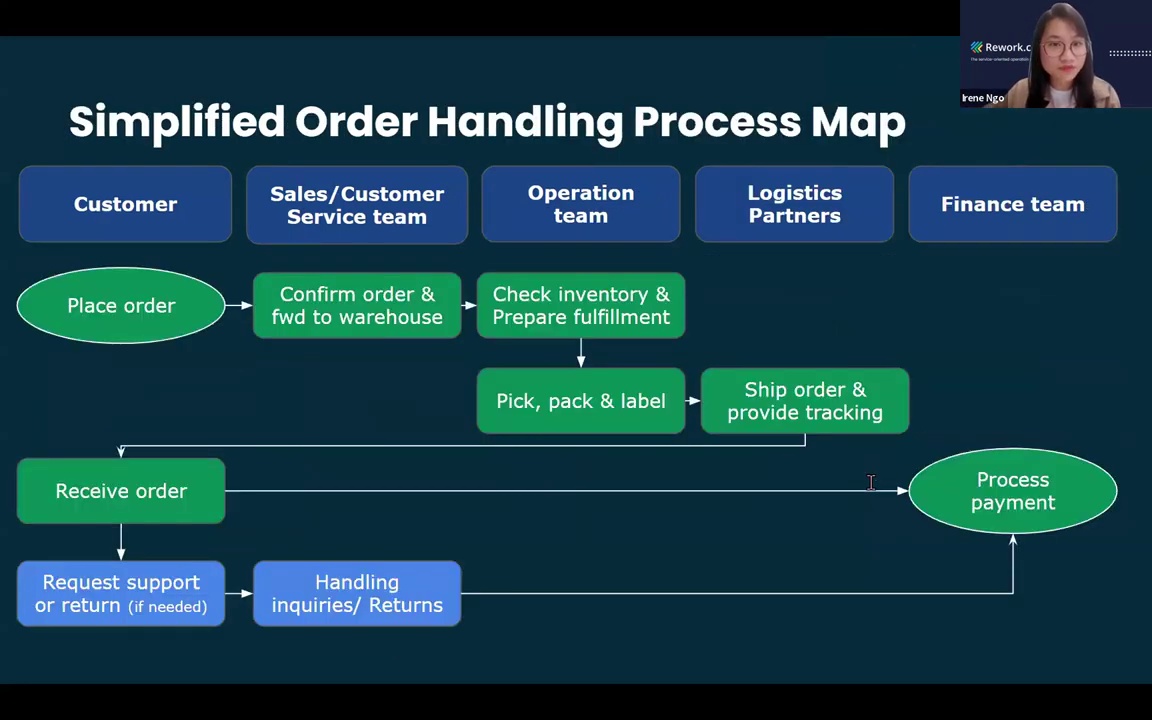

It starts with the customer placing an order. Then sales or customer service confirms details and forwards expectations internally. Operations and warehouse pick, pack, and get the order ready to ship.

Logistics takes over for delivery and route coordination. Finance handles invoicing, payments, or credit terms. Even though one order may look simple, it’s actually a collaborative relay race across teams.

Think of it like passing a baton—customer to sales, sales to operations, then finance. If any handoff fails, the whole process is delayed.

To simplify: when an order is received → it’s validated by sales → prepared by operations → delivered by logistics → and closed with payment. That’s the basic order handling flow.

Now let’s move into the system and see how we manage this end-to-end while ensuring smooth handoffs between departments.

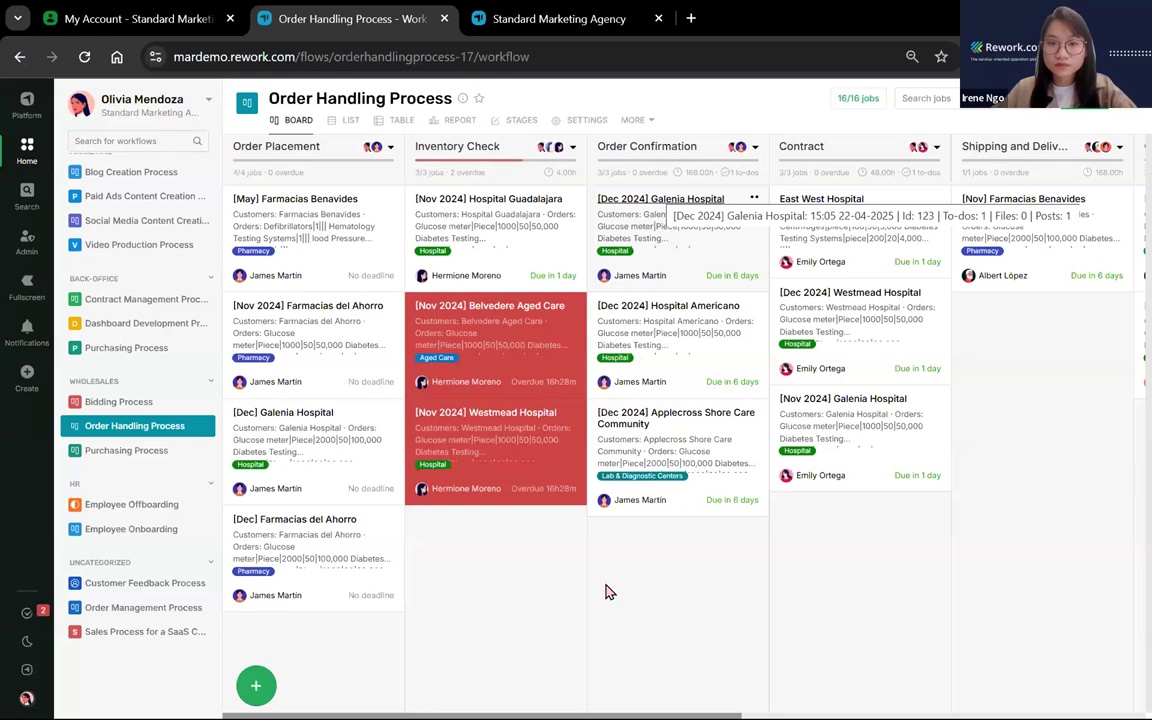

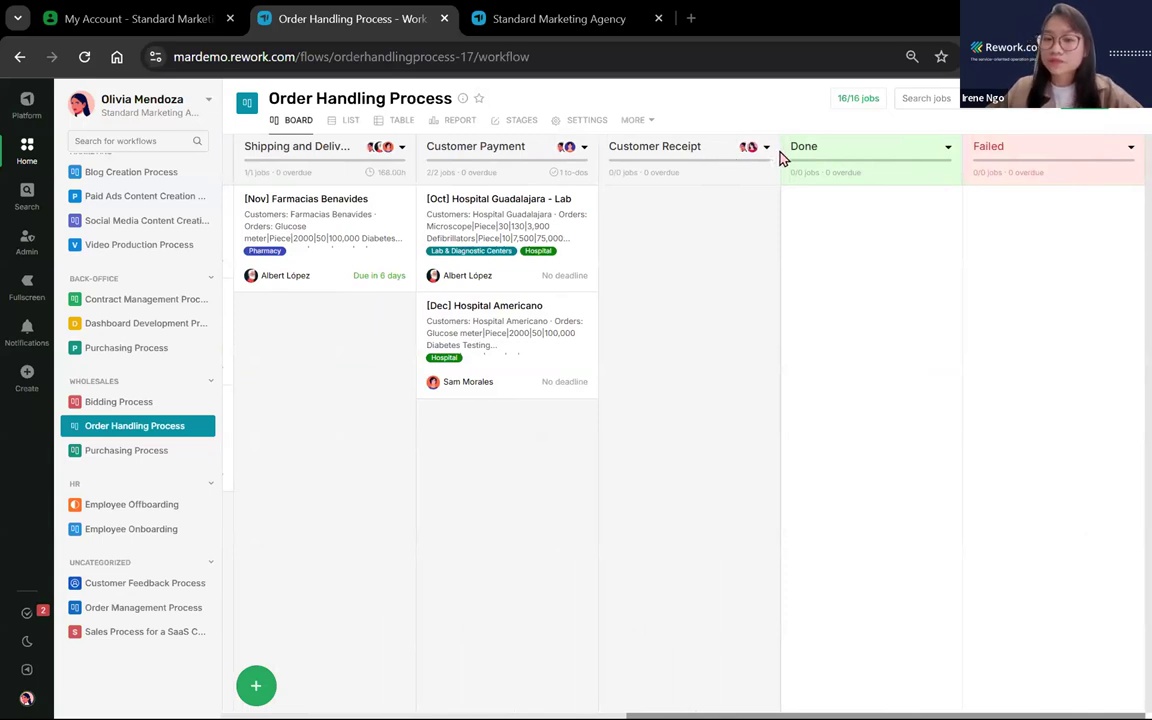

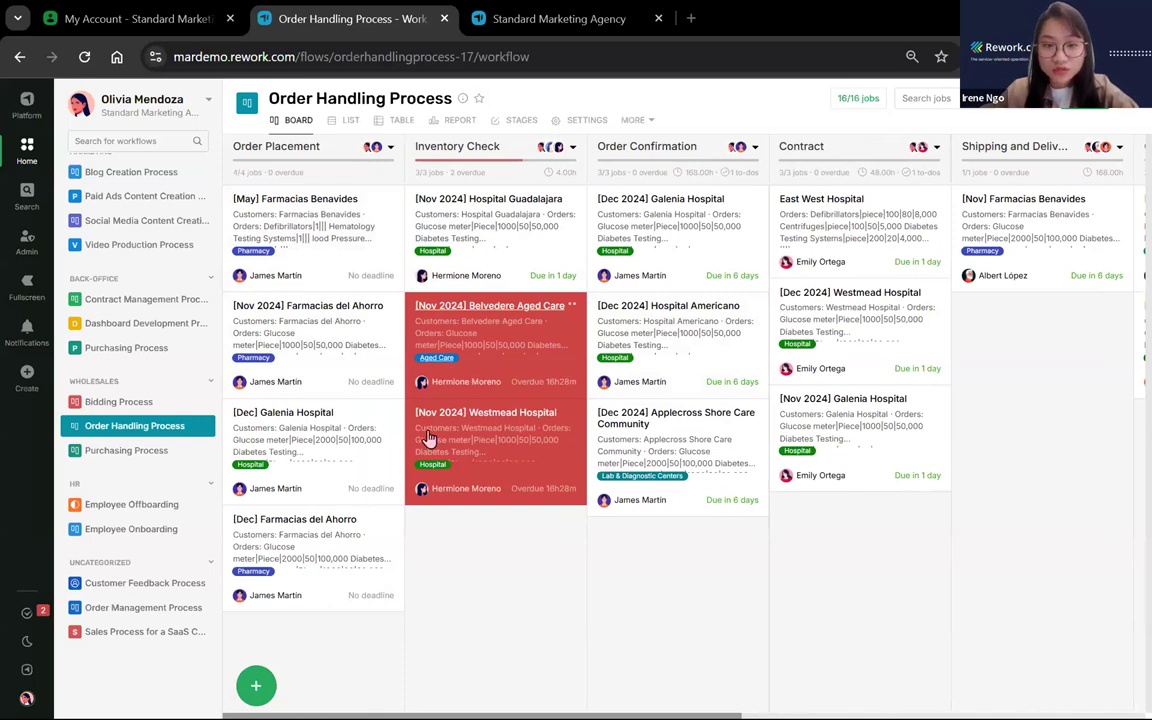

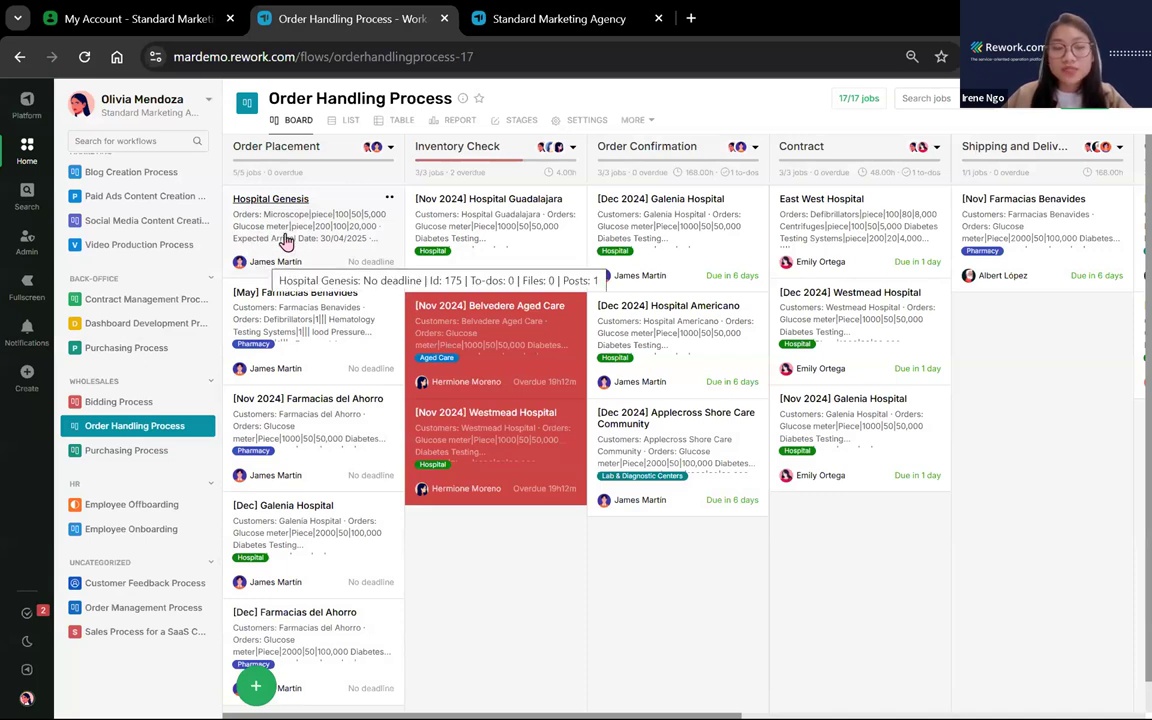

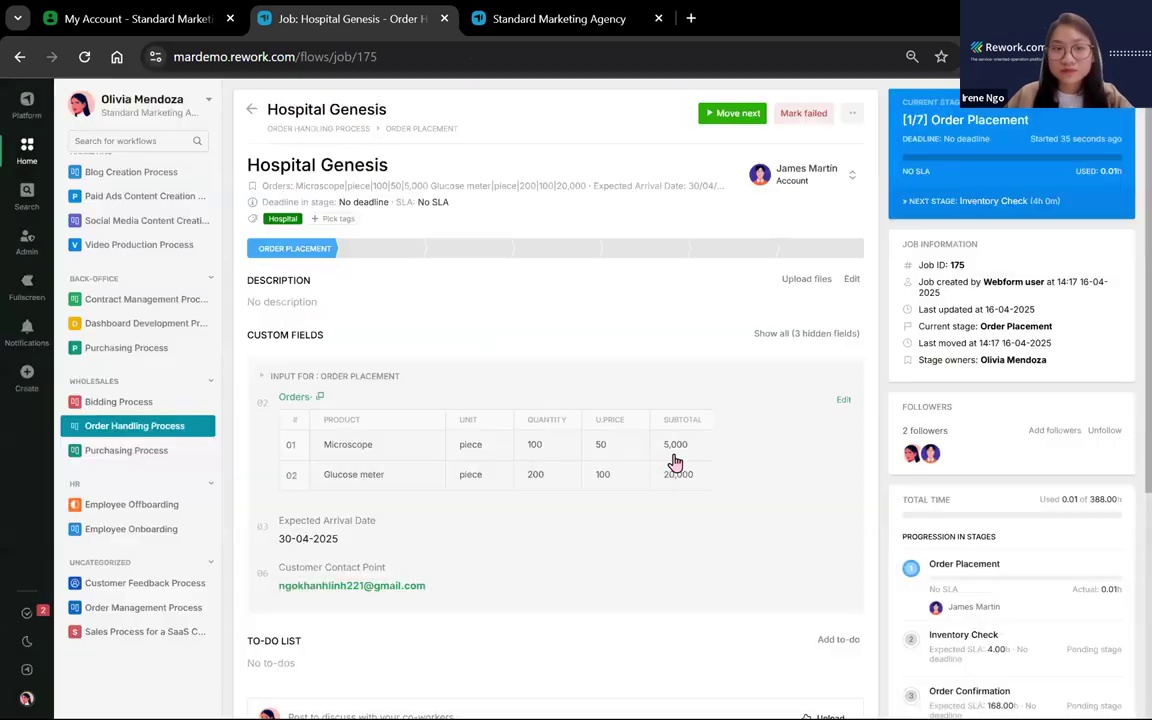

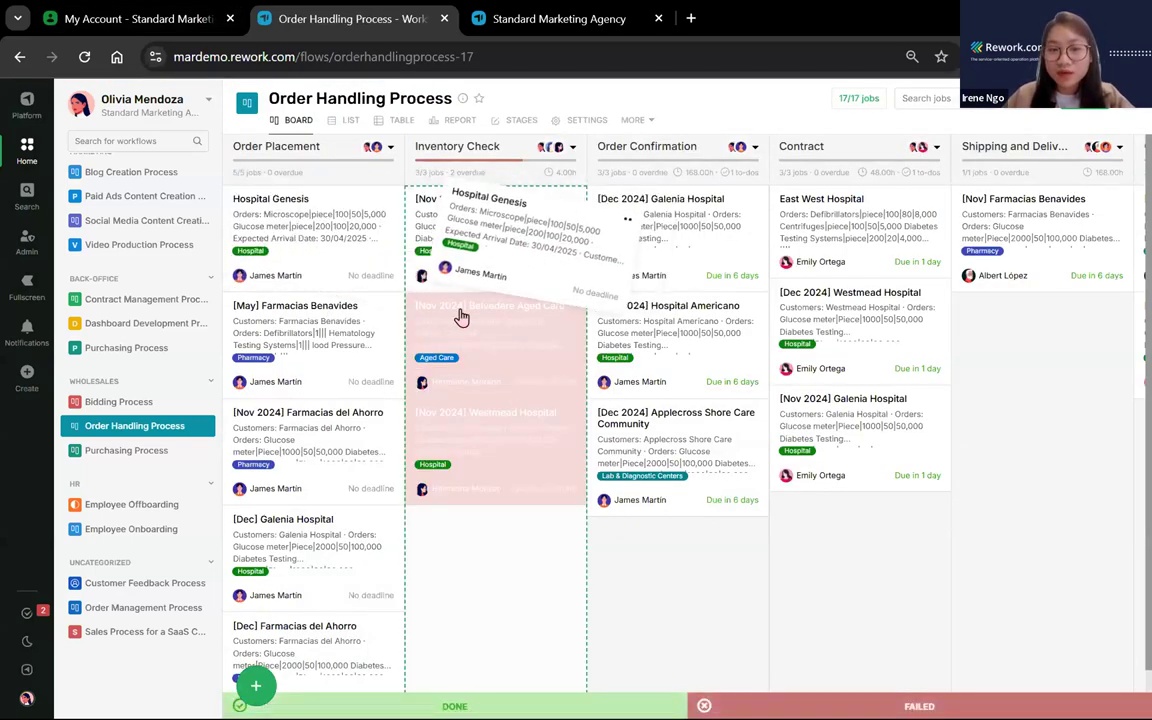

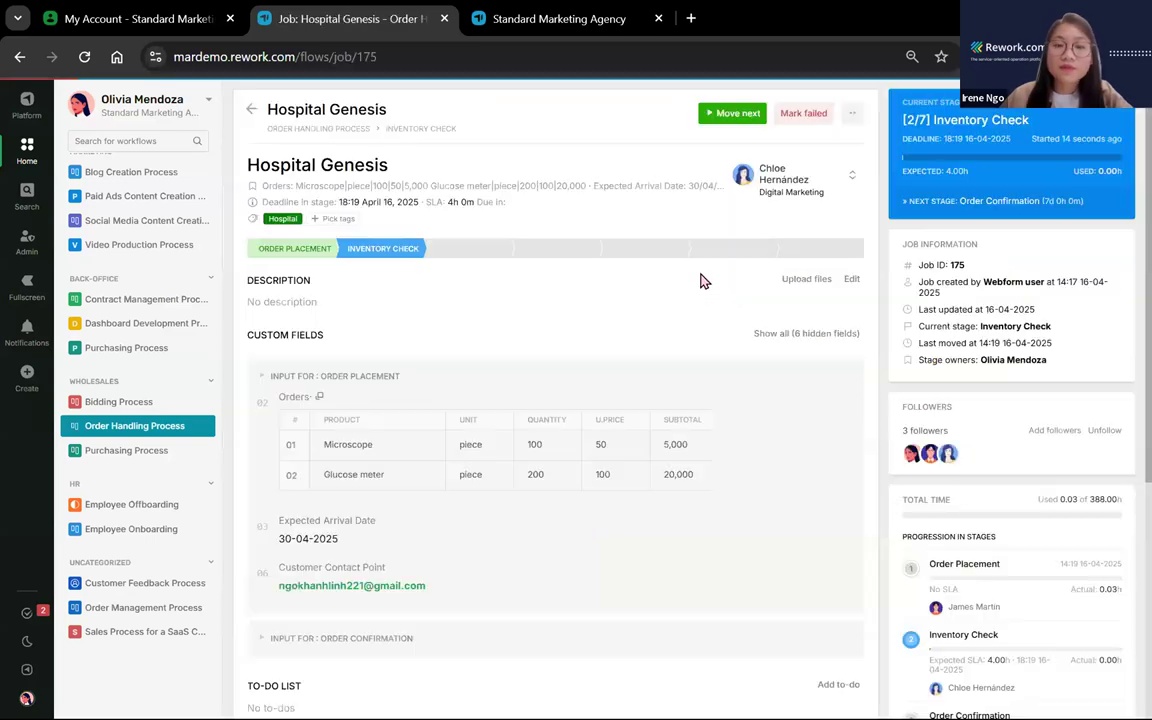

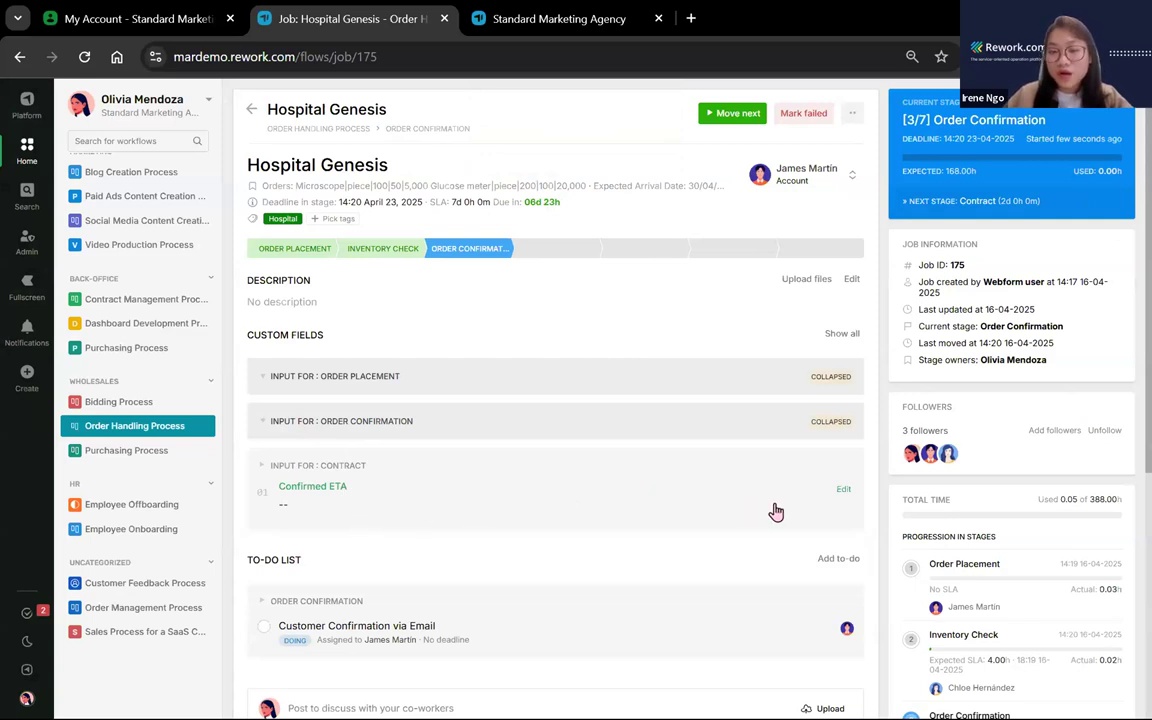

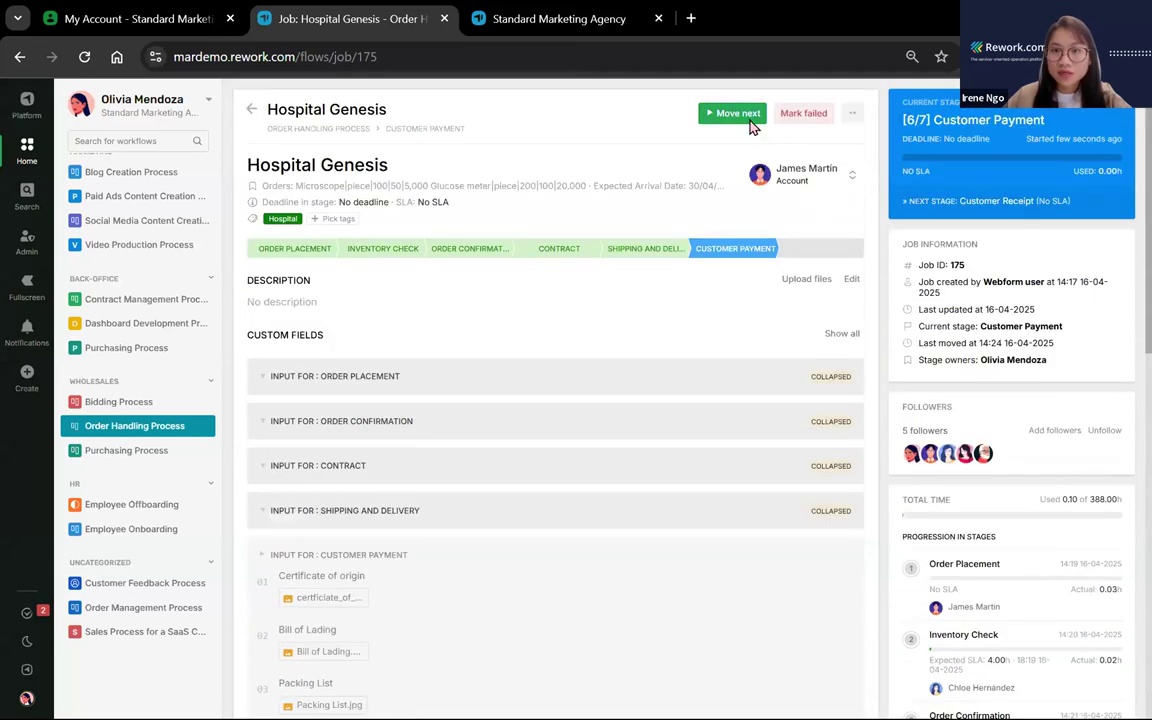

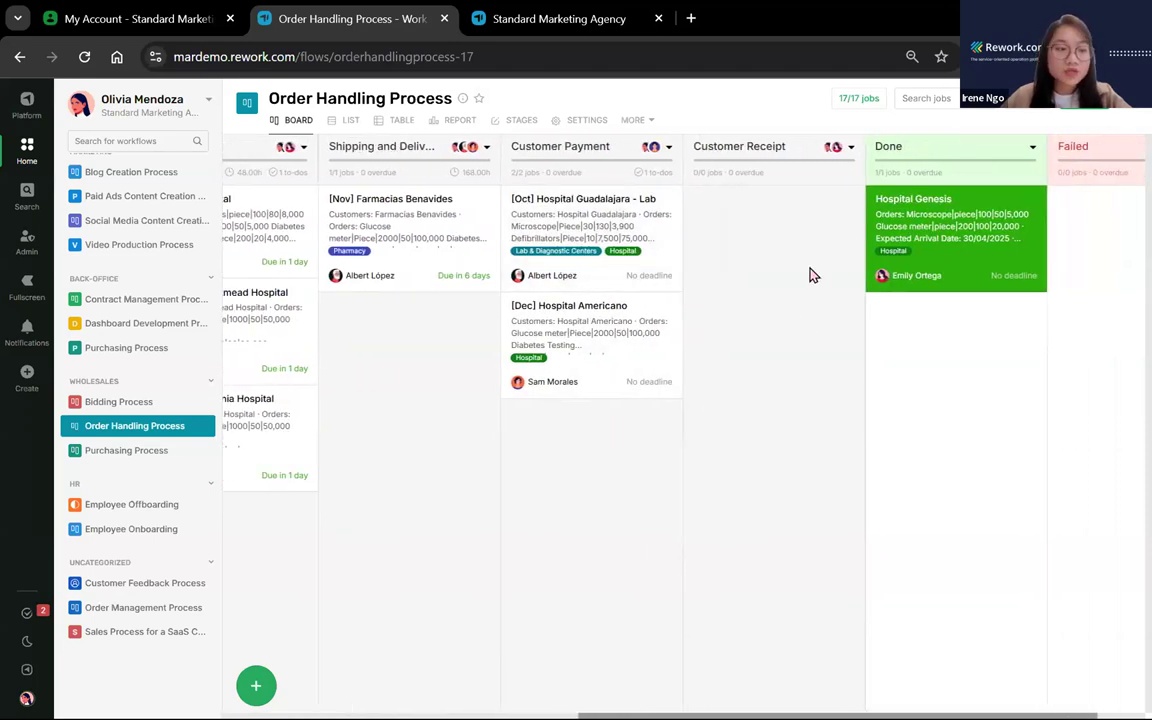

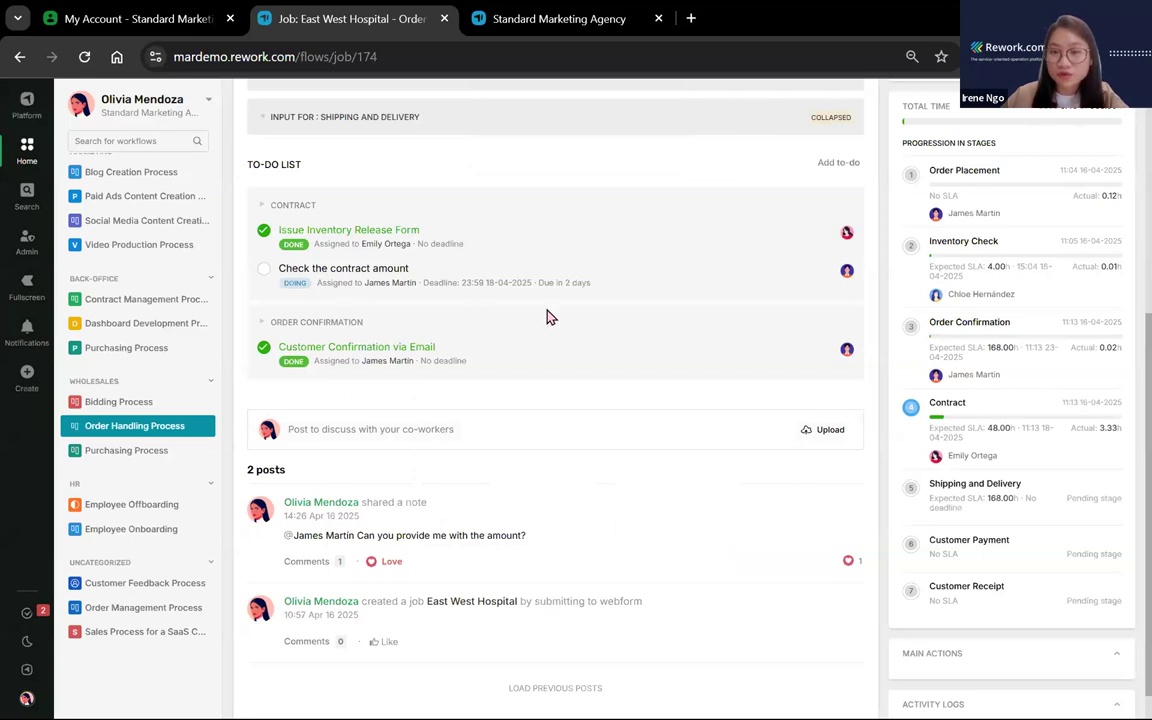

What you’re seeing now is a workflow inside our app called Workflows. This app lets you view and manage the entire process from beginning to end.

The example we’re using here is a medical supplies company. I chose this use case because it's a high-stakes, highly regulated industry—where delays and errors can literally impact patient safety. That makes it the perfect environment to demonstrate a strong process.

To showcase how a structural workflow in Flows brings transparency, speed, and accountability—which are all very critical for healthcare operations. I believe if it works here, it works anywhere, right?

So let’s get into it. From this one view, you can see we have different kinds of columns—or what we call stages: Order Placement, Inventory Check, Order Confirmation, Contract,..

Shipping and Delivery, Customer Payment, Customer Receive, and then it’s done.

So there's an input right here: Order Placement. And the output is when it's marked done, when we receive confirmation that the customer received it.

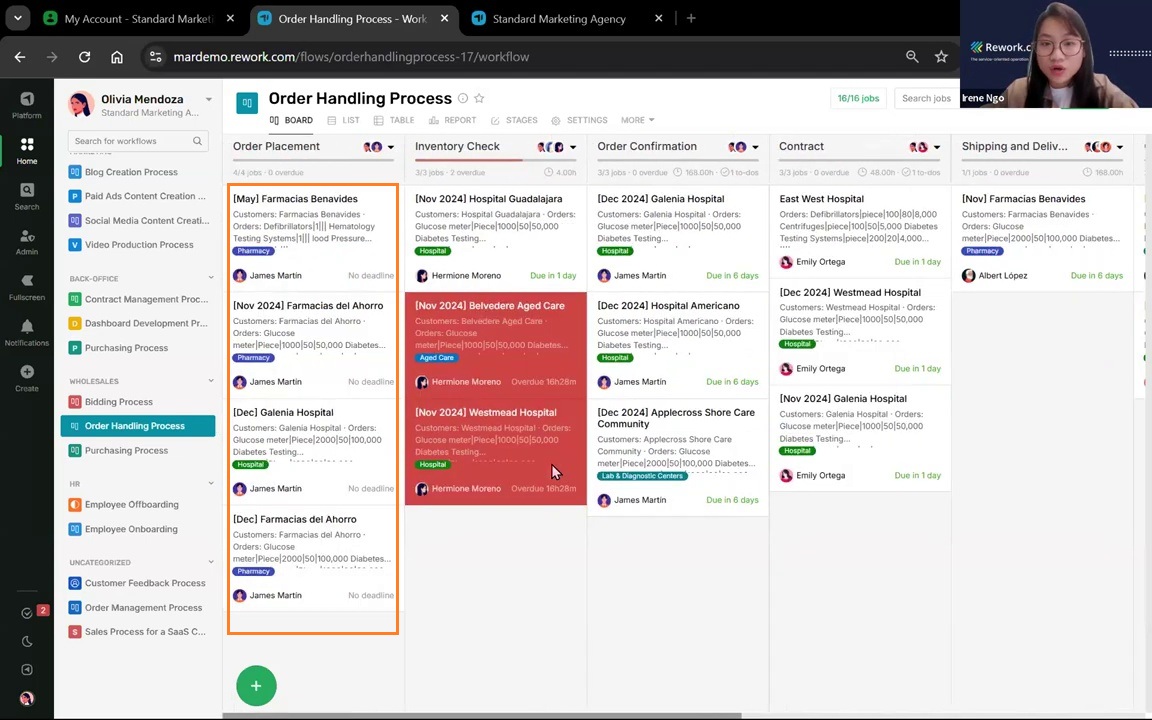

From one glance, we can see all of our orders and differentiate them by color—what we call cards. For example, white means it's in progress, red means it's overdue, and green means it's done. Each card is assigned to a specific person.

Everyone knows exactly what's on their plate. For example, James knows he has four orders. We can also see timing some are due soon, others are overdue.

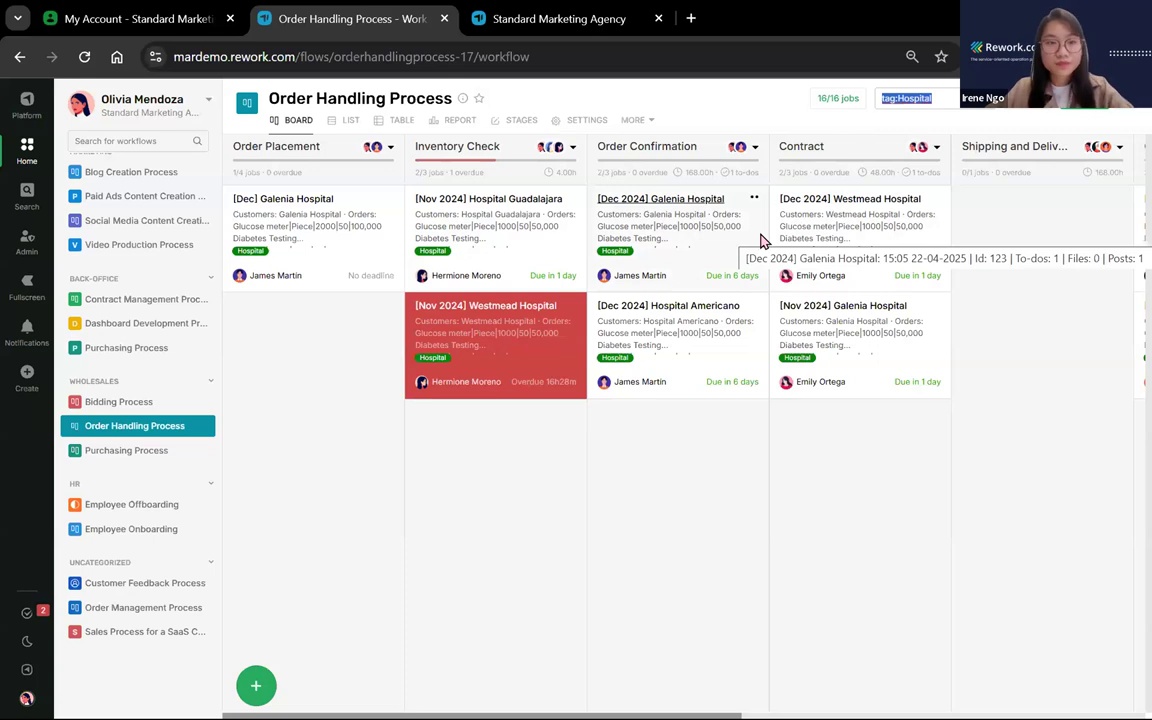

This company receives orders from hospitals, pharmacies, aged care centers, and diagnostic labs.

Using tags, we can filter and see, for example, how many hospital orders we have 16 jobs in this case.

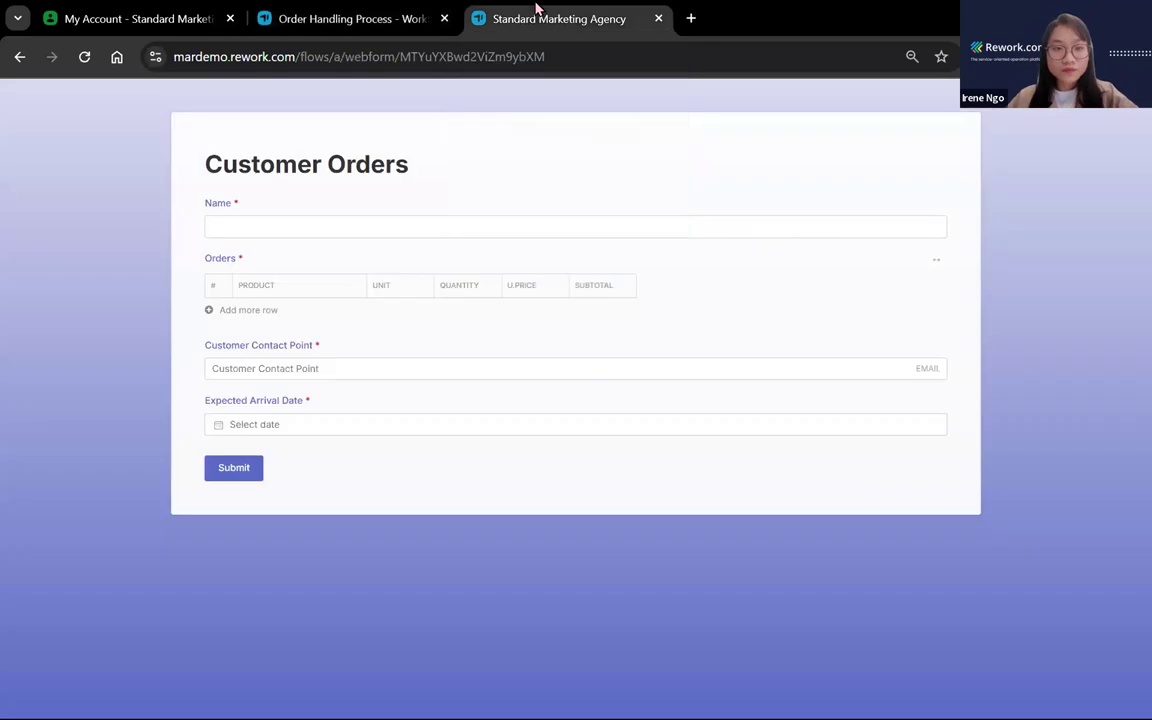

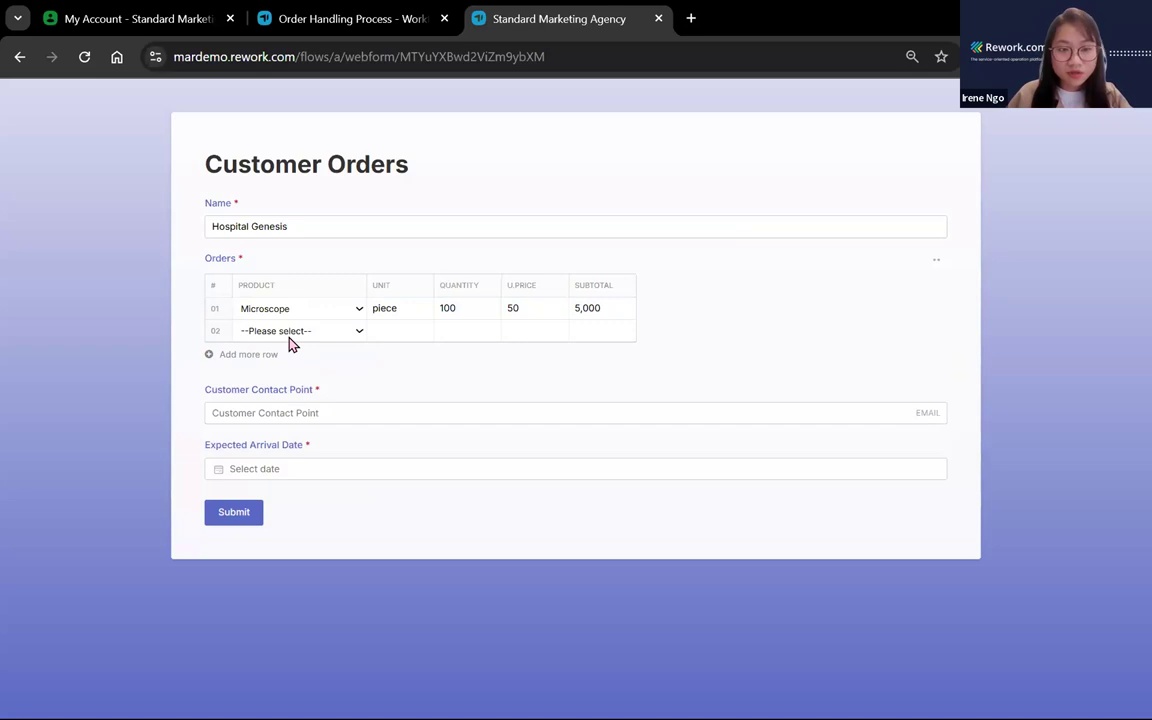

Now, how do we receive orders? We suggest using a web form. When a customer fills this out, the order is sent directly into the system.

Let’s say I’m Hospital Genesis. I select products like microscopes and glucose meters, enter quantities, price, contact email, and expected arrival date. Then click submit.

After submitting, a job is created and automatically assigned to James. He gets a notification, opens the card, and confirms it’s from a hospital using a tag.

Then James checks the clarity of the order—sometimes customers don’t fill out everything. He might call to confirm missing info.

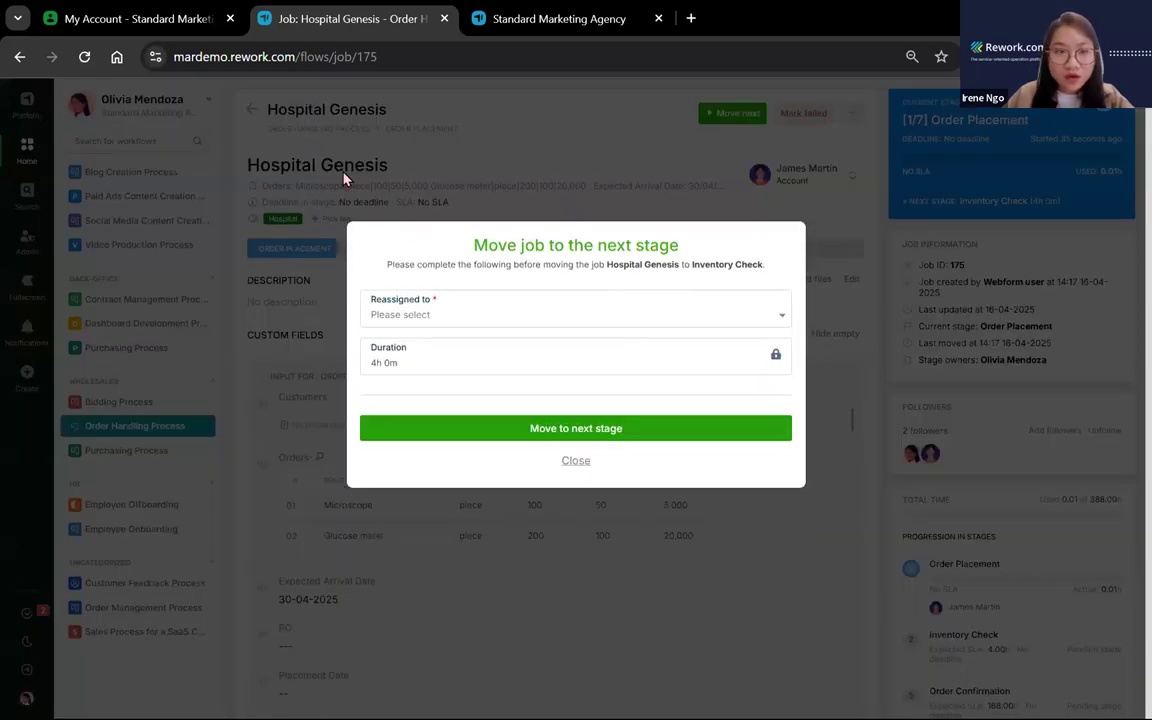

Once it's clear, he sends it to the inventory team.

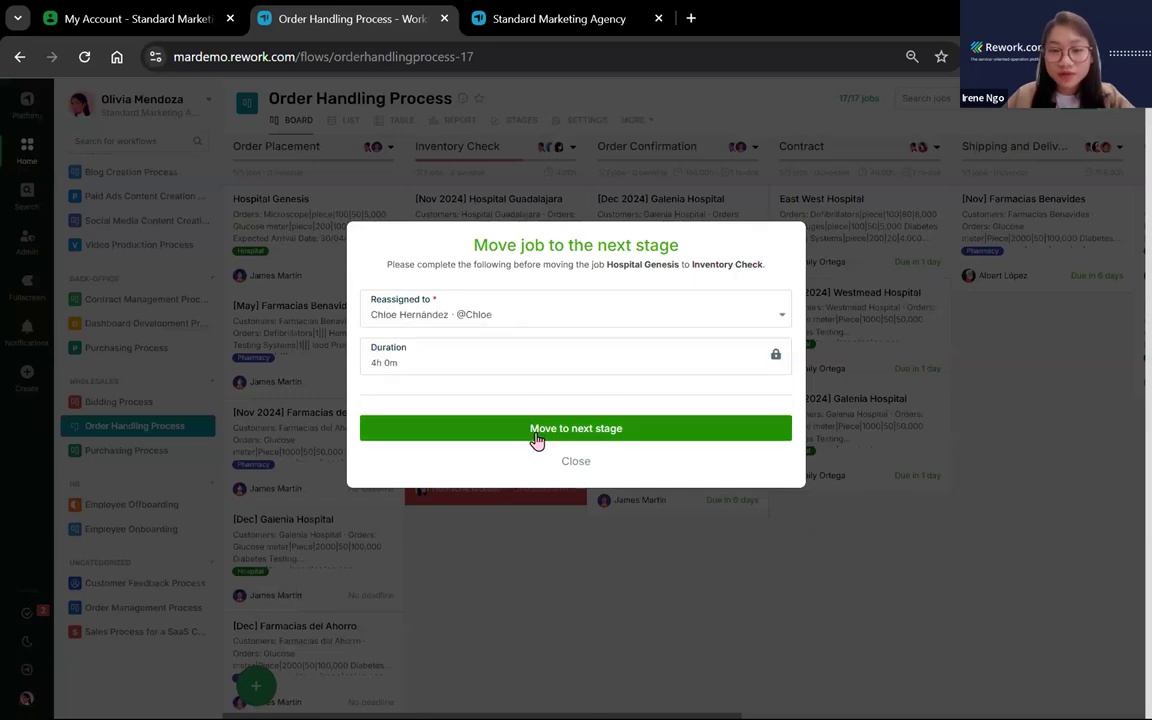

(Another way) James can drag the card and reassign it to Chloe.

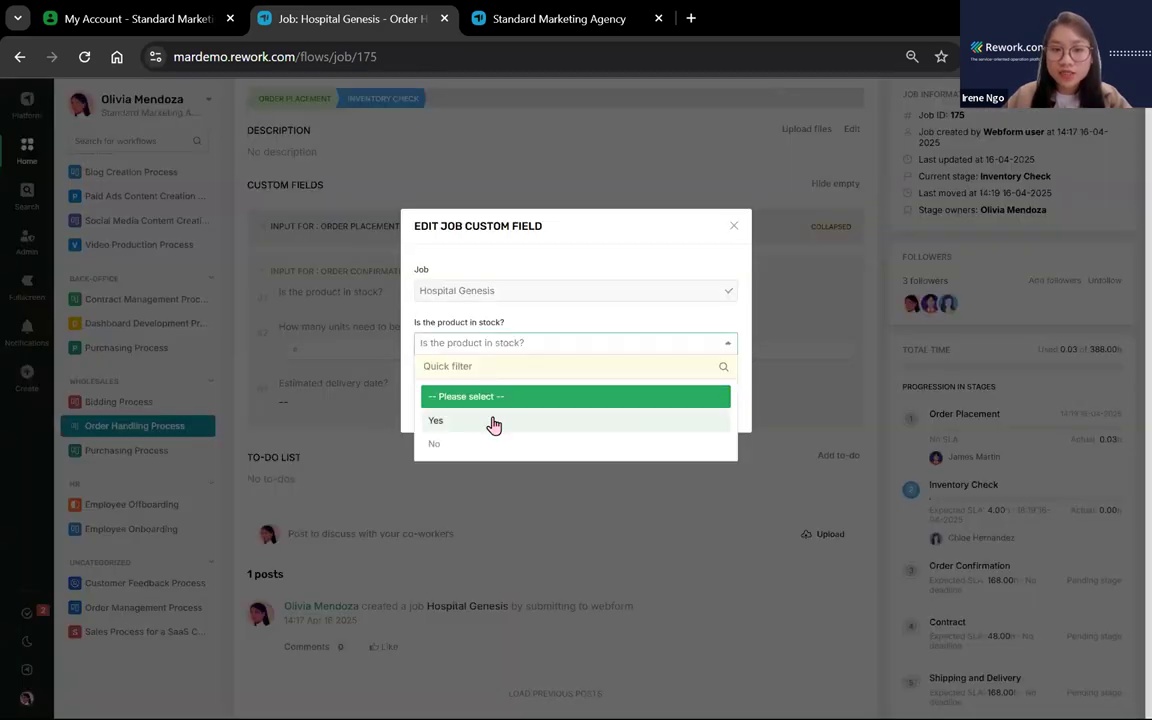

Chloe gets notified and checks inventory.

She clicks a button, confirms the product is in stock.

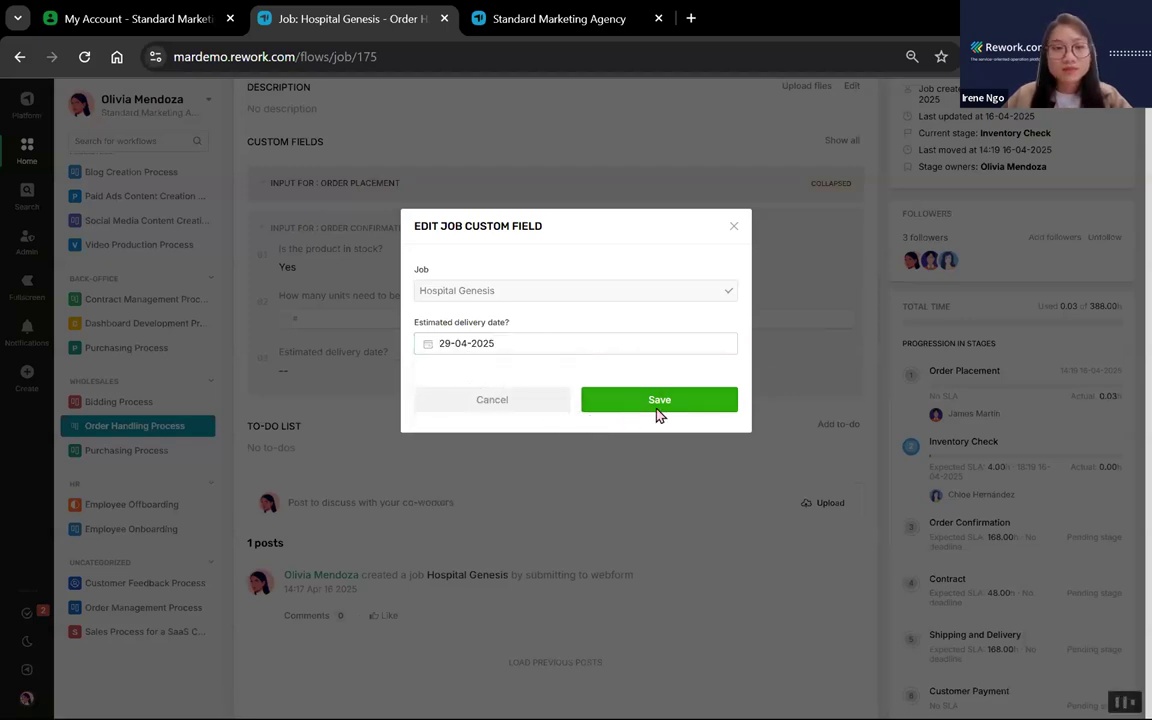

Adds estimated delivery date, and skips supplier ordering if unnecessary.

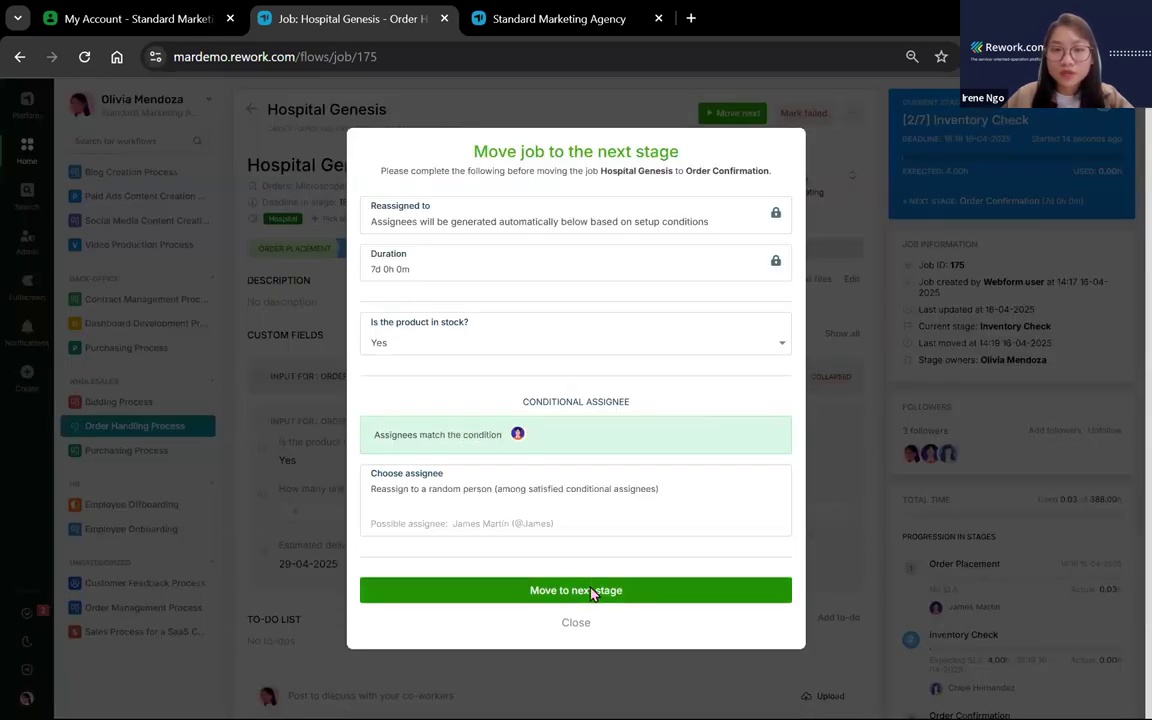

Then Chloe moves the task next to James for order confirmation.

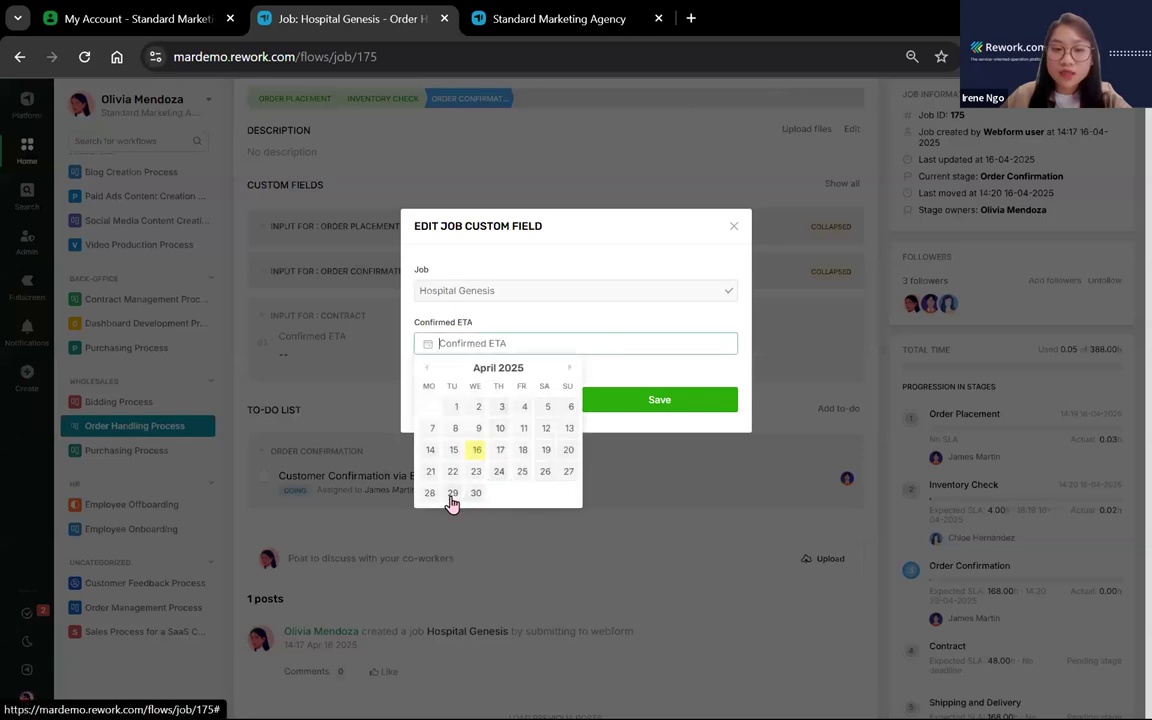

James now confirms the delivery date with the customer.

Let’s say the 29th. He notes it in the system, clicks done,

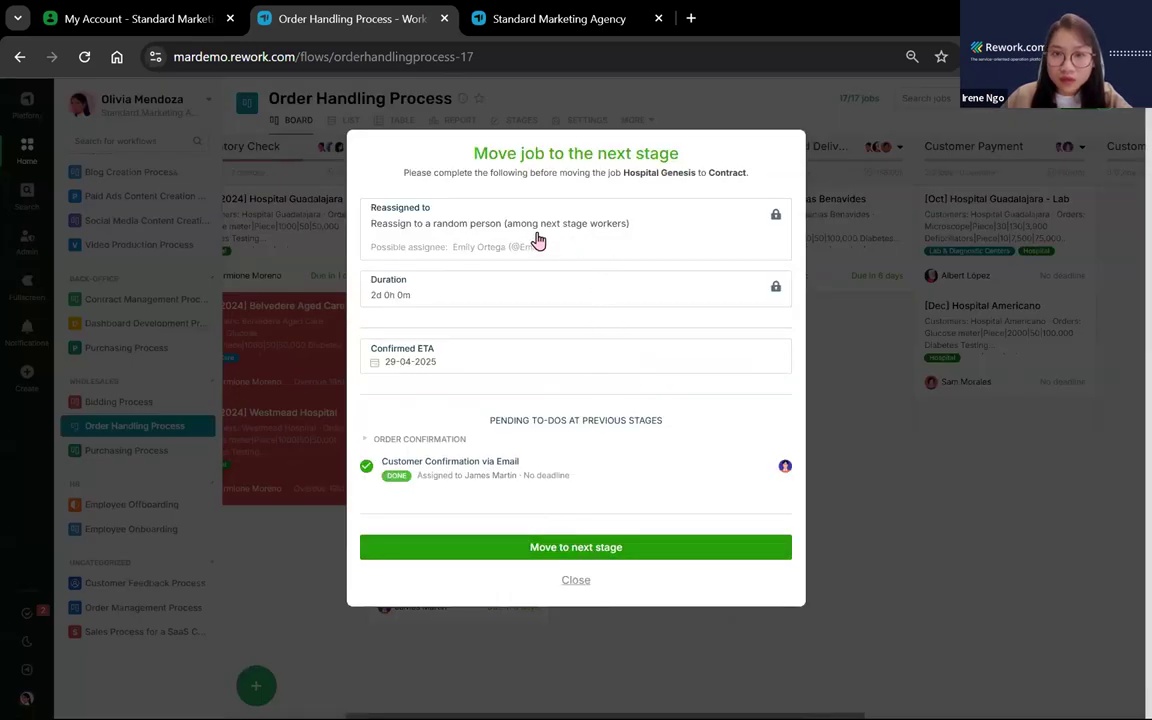

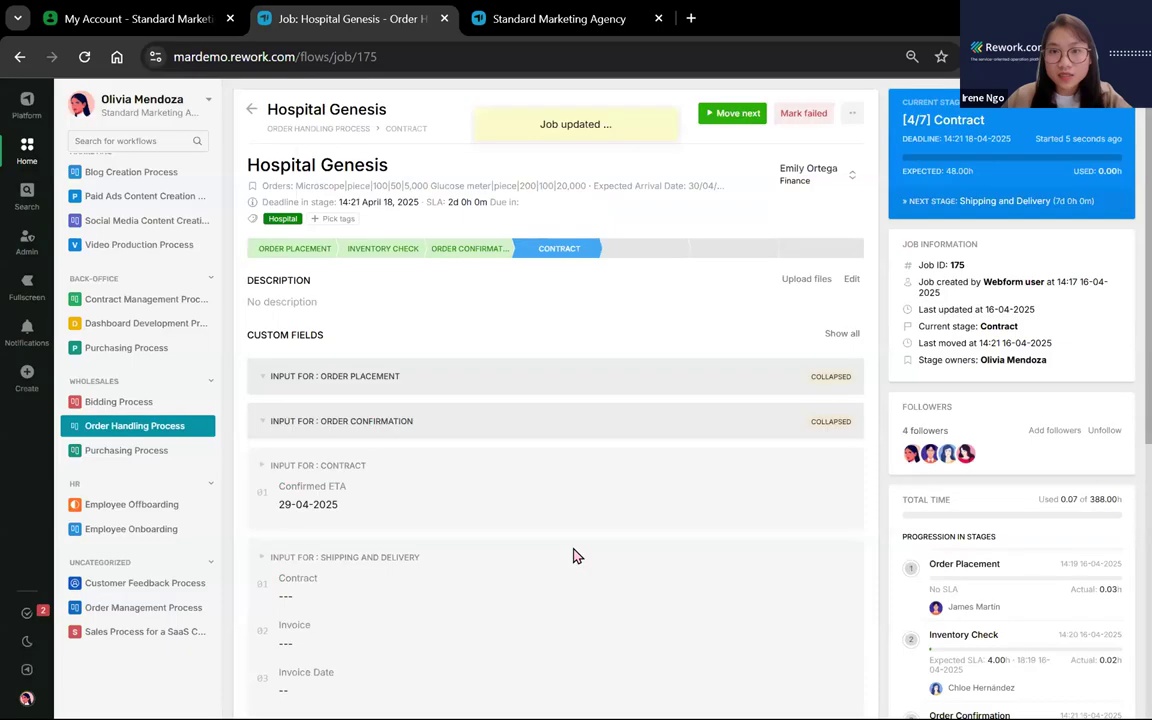

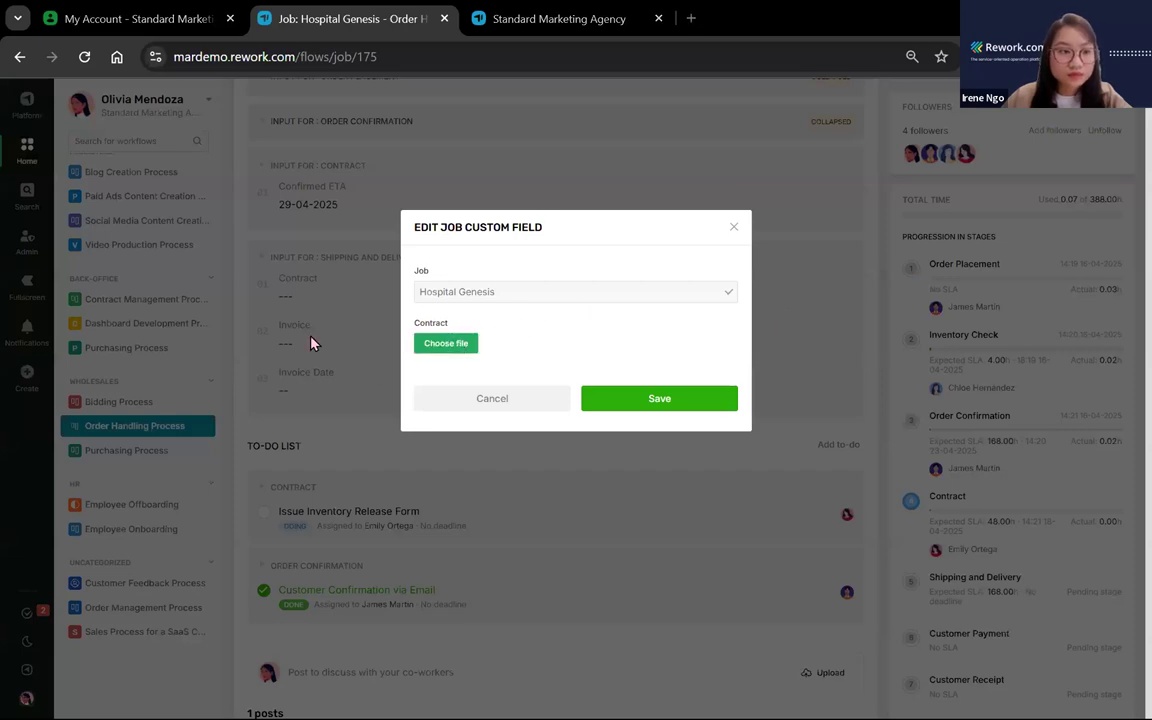

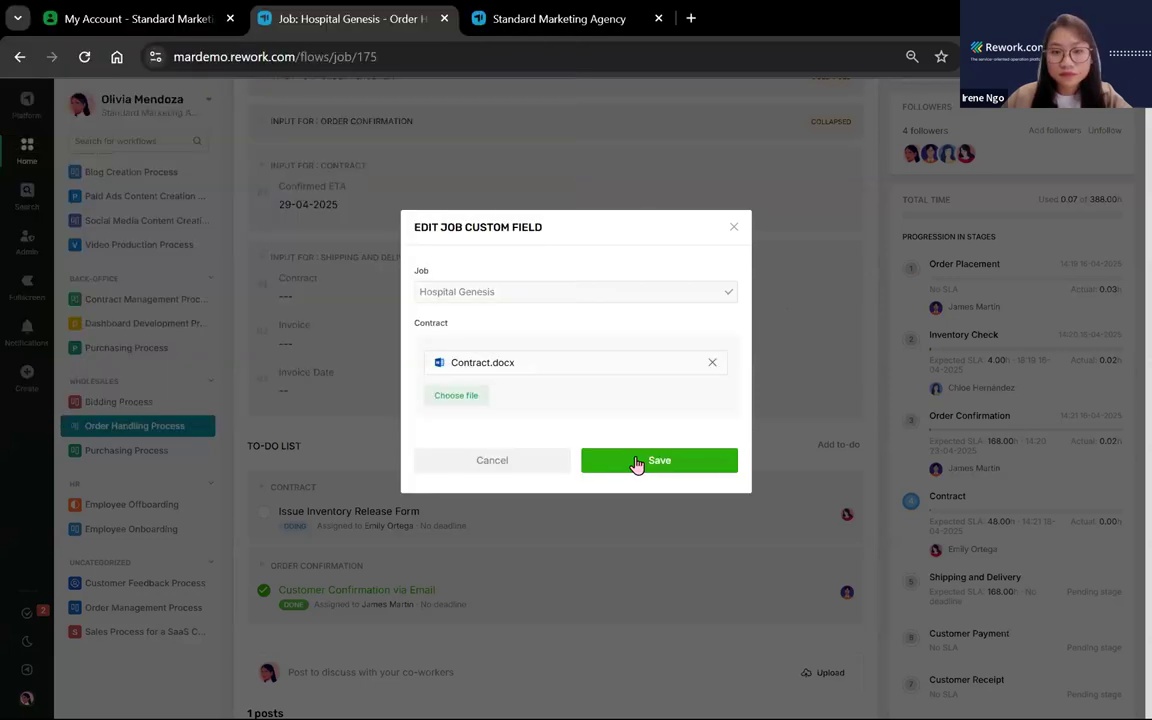

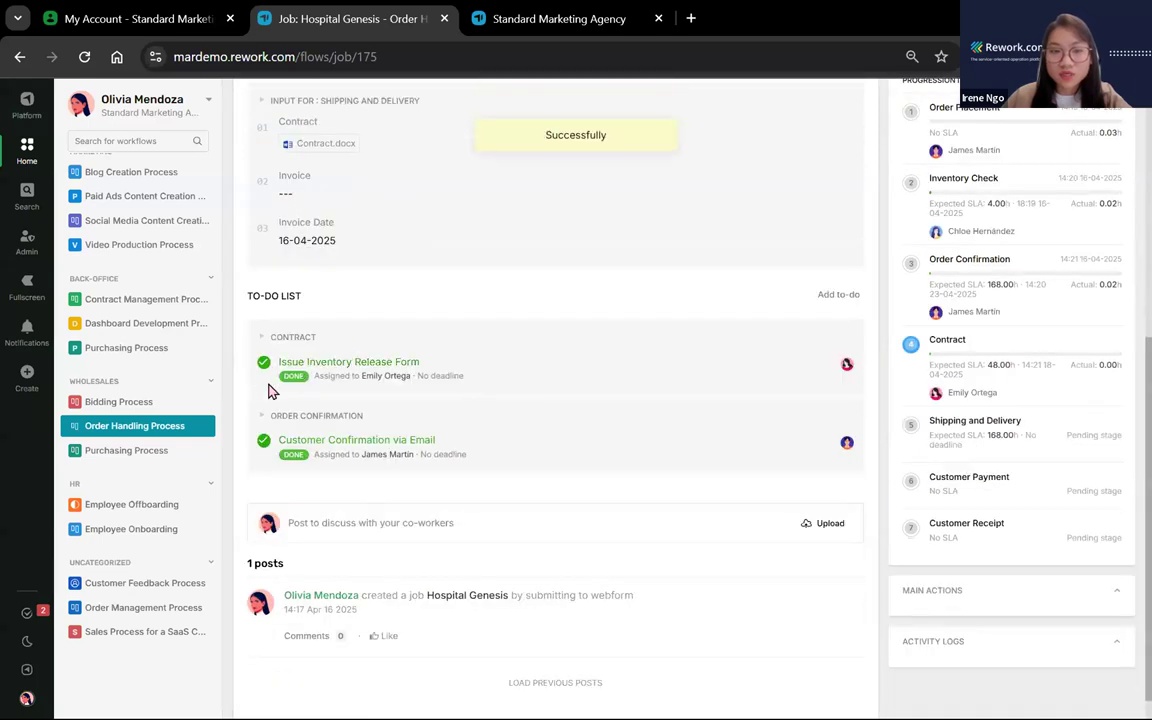

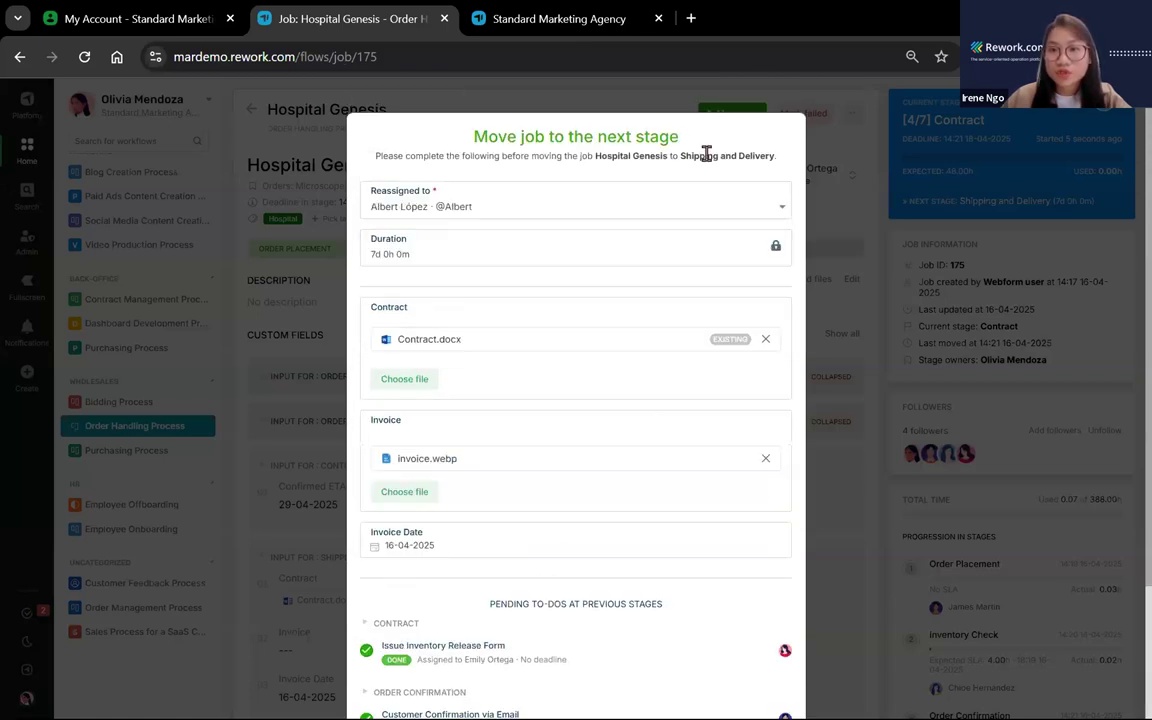

and moves to the next step: contract preparation.

Then he uploads the invoice

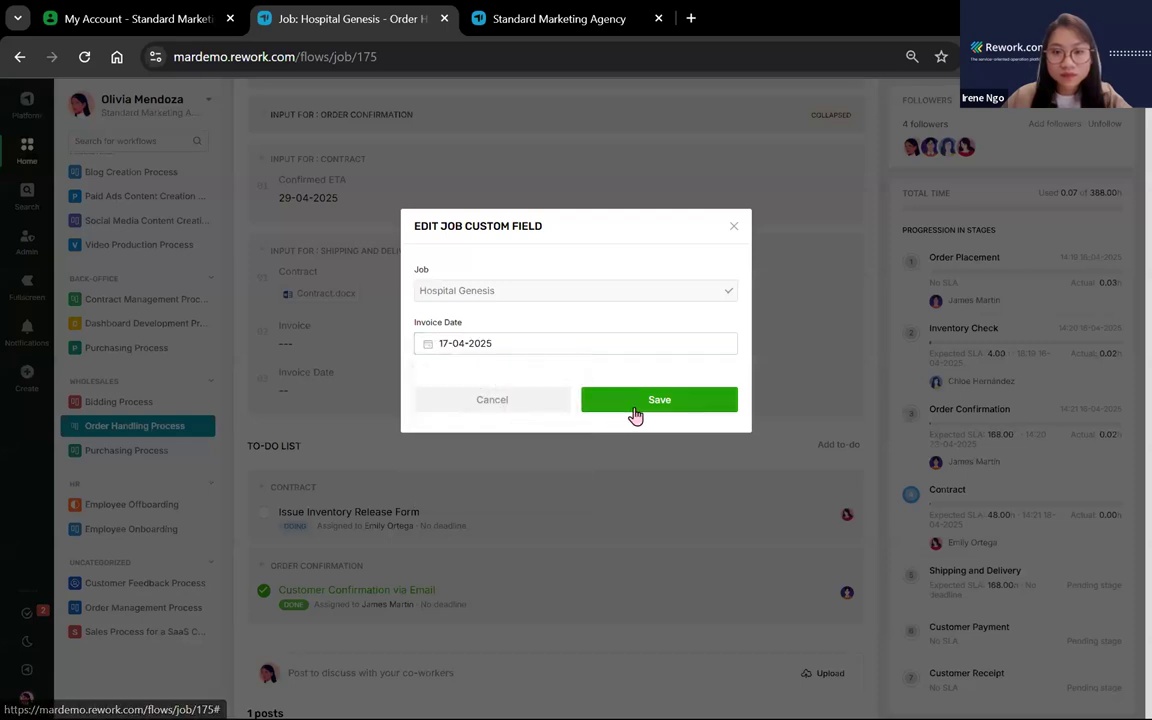

invoice date,

and issues an inventory release form.

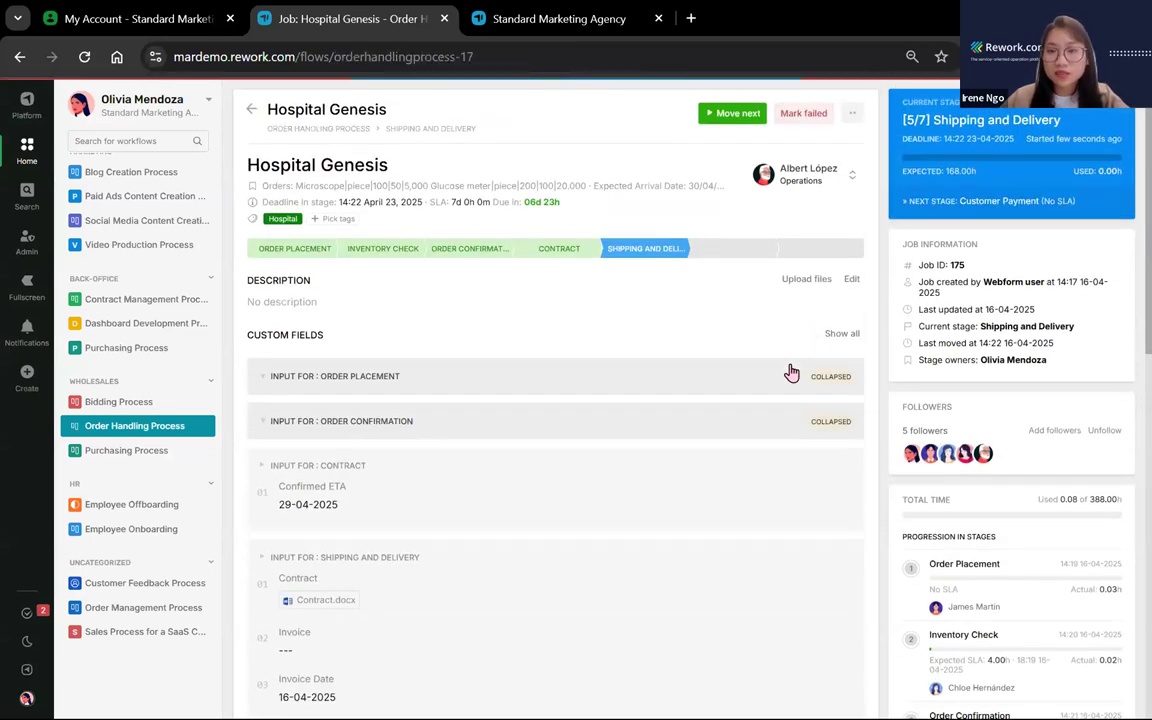

Then reassigns the task to Albert for shipping and delivery.

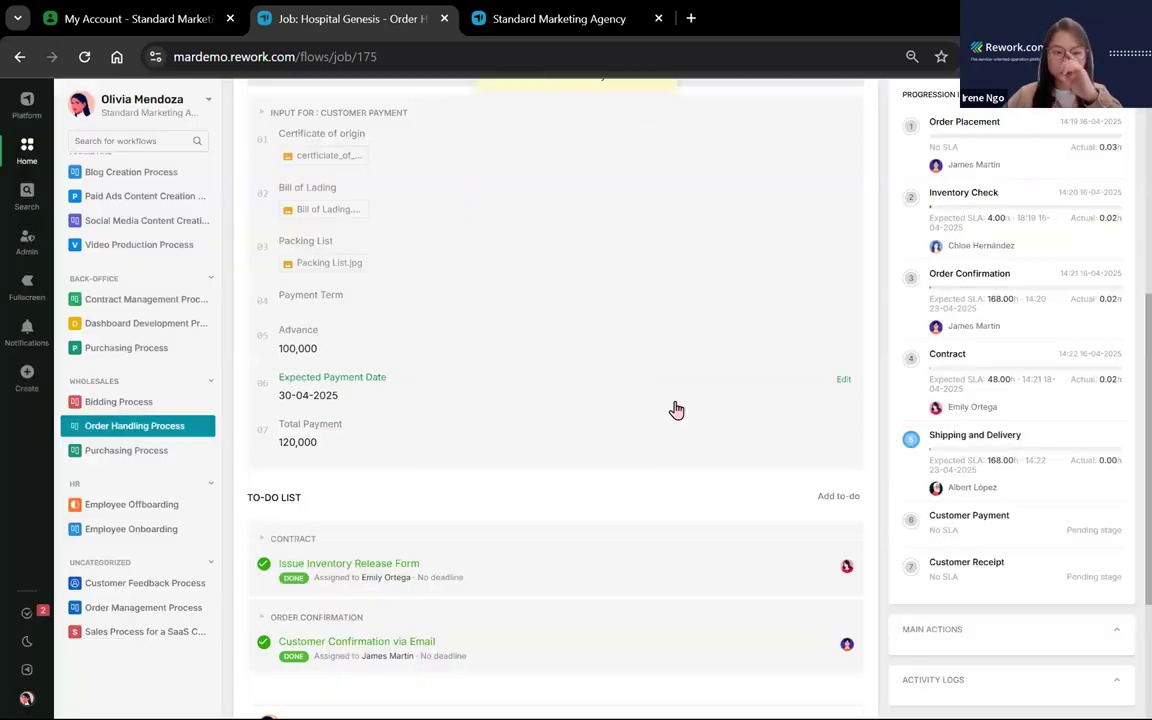

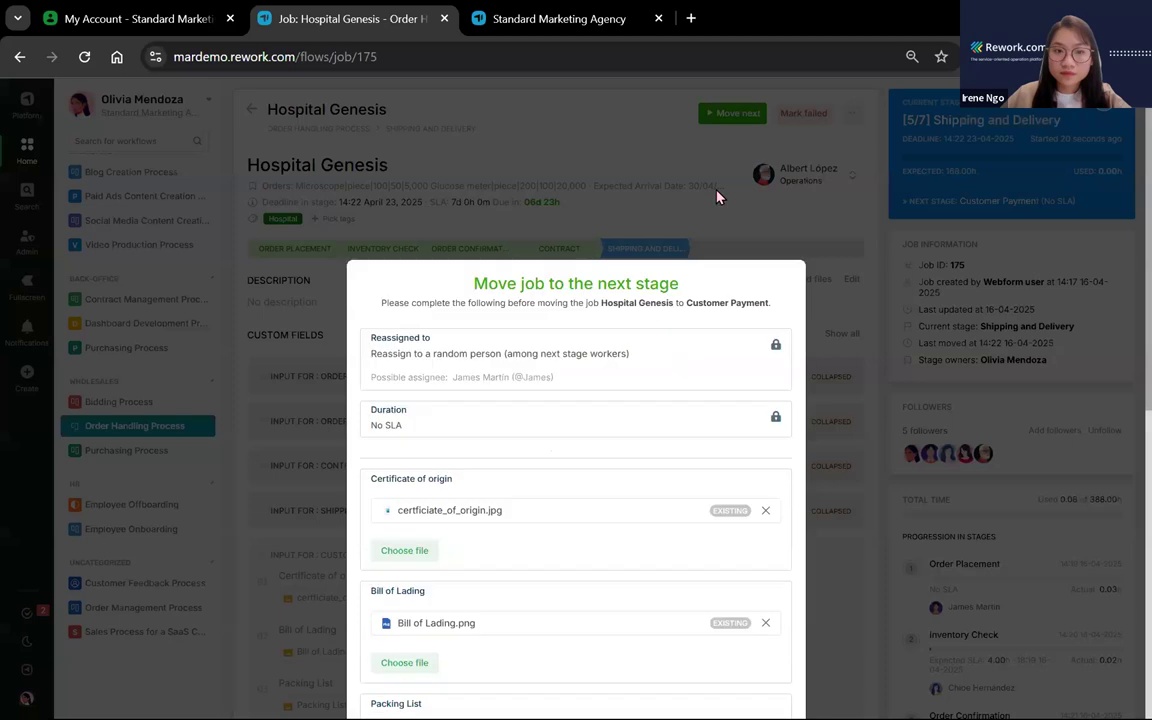

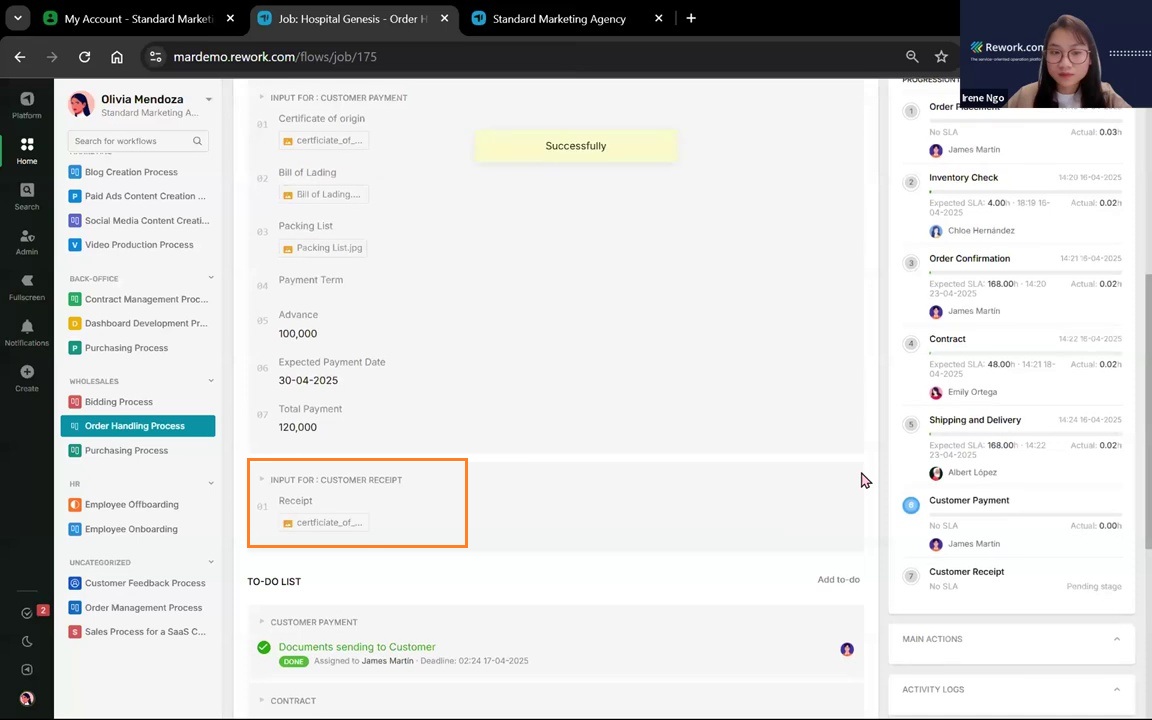

Albert now uploads relevant documents:

certificate of origin, bill of lading, packing list, and sets expected payment details.

Next, the task is moved back to James to follow up with the customer for payment.

Once payment is received, he uploads the receipt and sends it to finance.

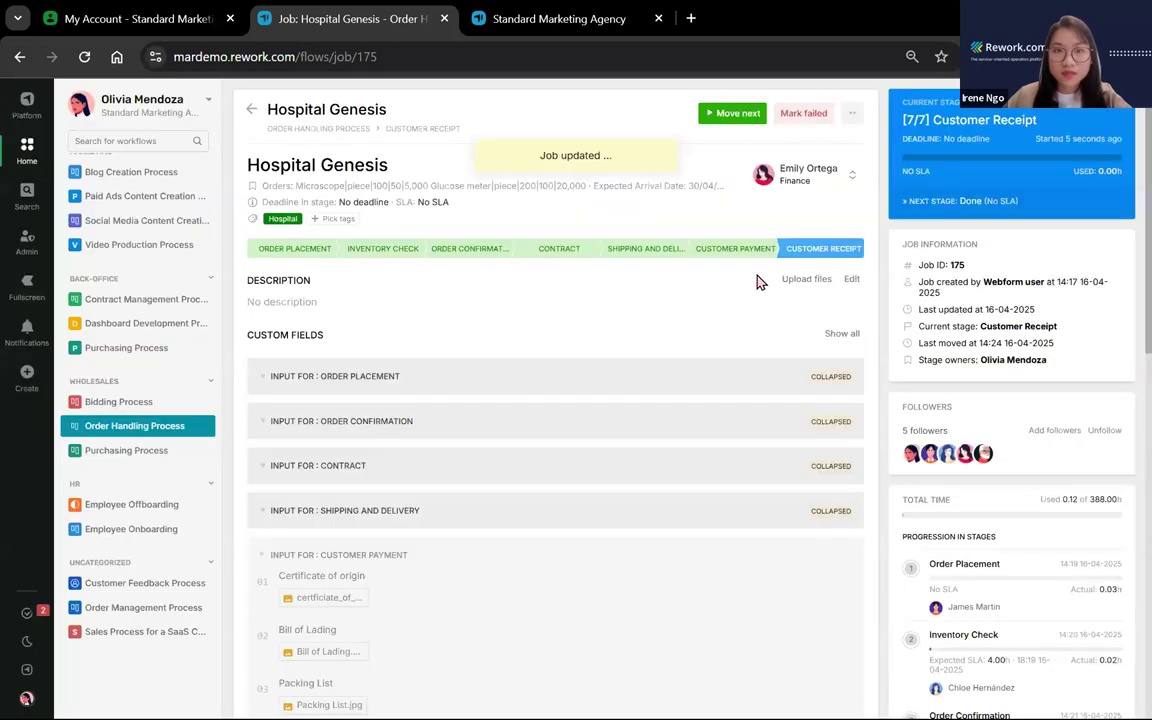

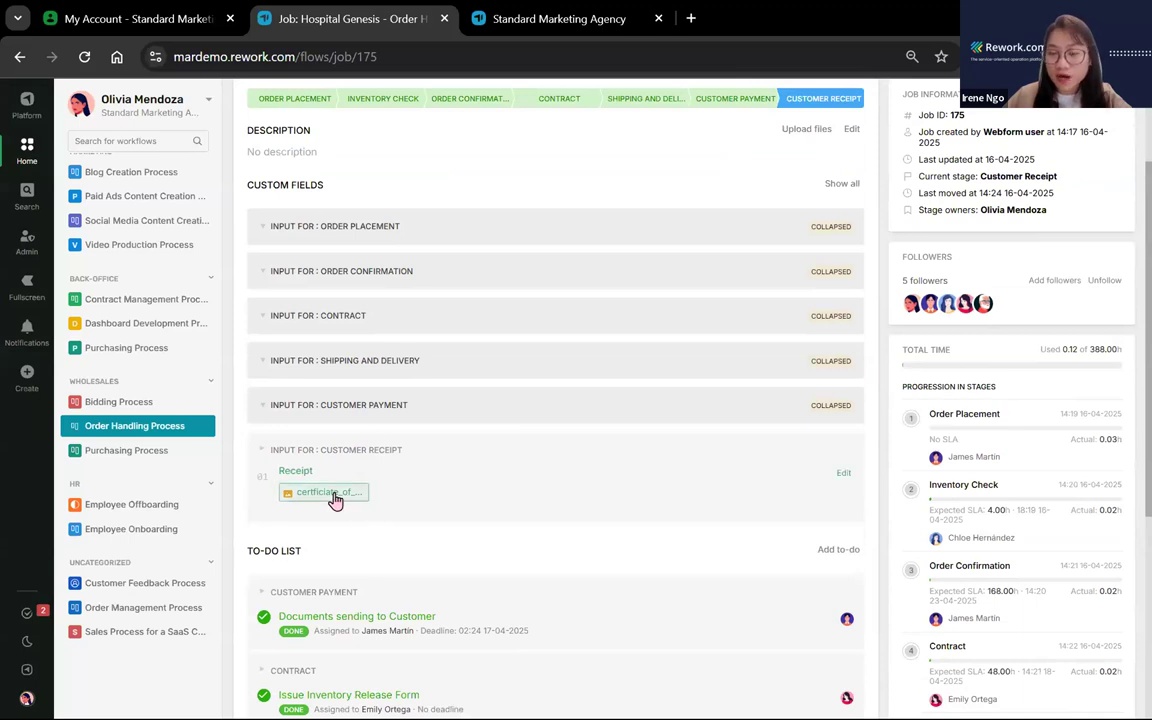

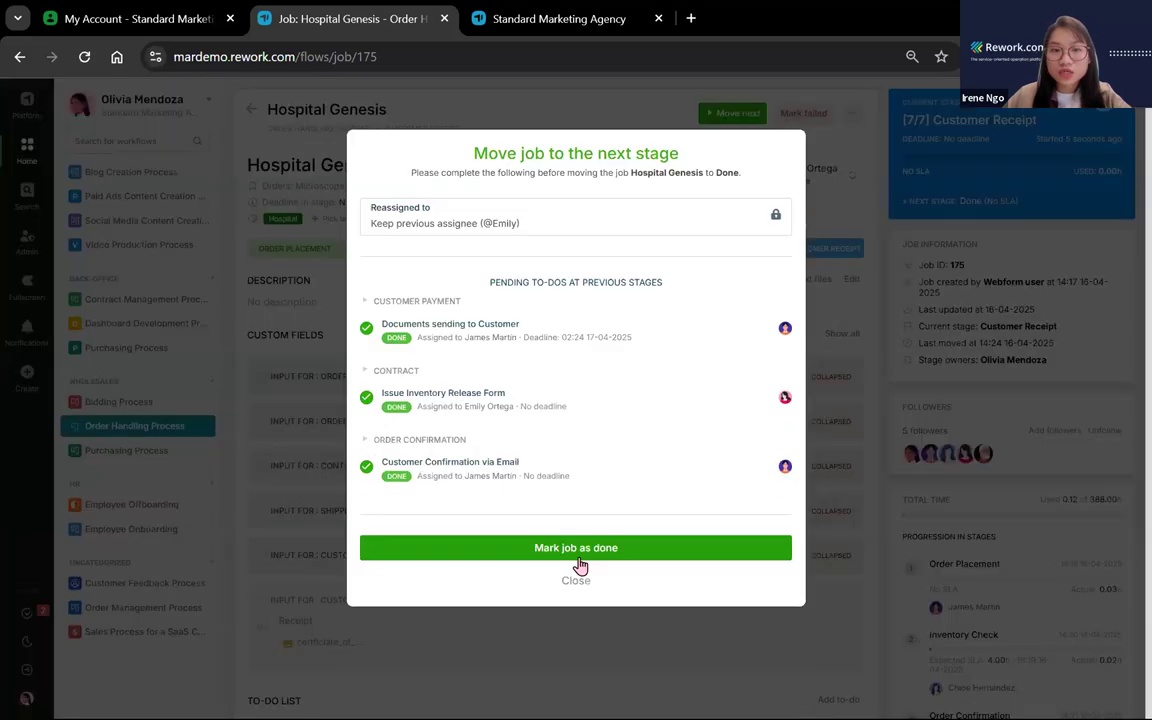

Emily from finance checks the receipt.

She opens the file, reviews it,

and marks the job as done.

So this was the entire flow—from sales → operations → sales → finance → logistics → sales/finance again. Each department is involved and everything is tracked in one view.

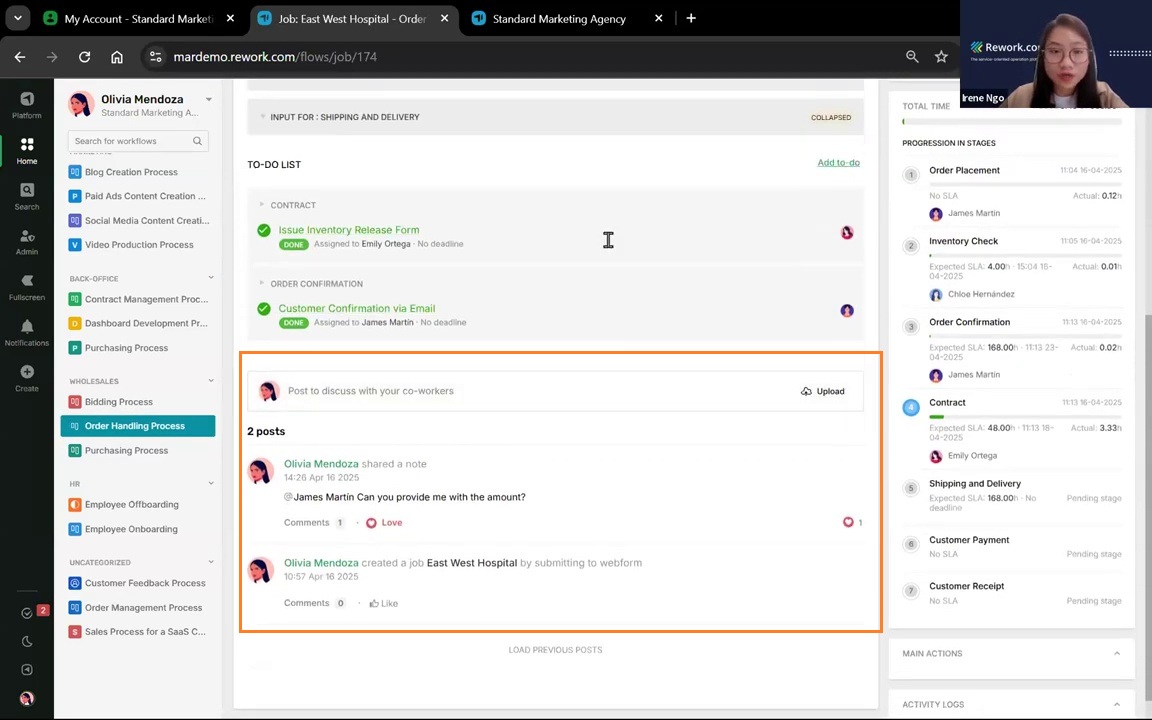

Now, how do they communicate? Not just through documents. There are adjustments and collaboration too.

For example, if Emily needs missing information, she can comment and tag James. James is notified, replies, and updates the info—all in the task context.

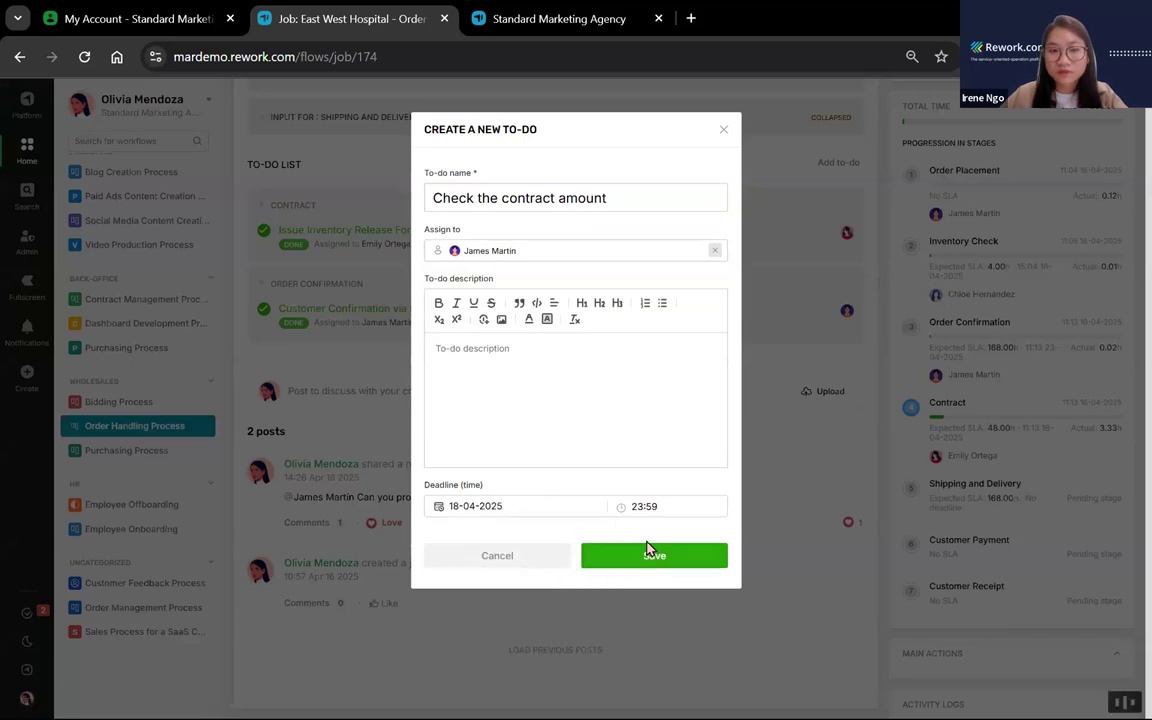

You can also assign to-dos. For example, “Check contract amount” with a deadline.

It appears in James’s to-do list so he knows what to do before the task progresses.

That’s how this order handling process flows—end to end—with visibility and structure.

After the demo, I hope you have ideas or questions. Feel free to drop them in the chat!

Someone asked: can this integrate with website, accounting, and WMS?

At the beginning, I mentioned those systems are ERP-centric—centralized, data-driven platforms. Rework doesn’t replace ERP. It complements it. ERP holds the records, and Rework ensures the work happens—efficiently, visibly, collaboratively.So yes, Rework connects teams, while ERP holds the data. Rework makes the process operational.

Next question: can we assign due dates for each process stage?

Yes, absolutely. We can define turnaround times for each stage. For example, inventory check within 2 days, delivery in 7, etc. The timeline can be adjusted per order based on customer urgency. Internally, we control standard durations, but customer needs can override them.

Another great question: can Rework generate unique PR or PO numbers?

Yes. Each job gets a unique job ID—like Job 173. You can use this ID as your PO or reference number.

Next question: can we bulk upload files?

Yes. Rework supports importing jobs from Excel. We provide a template, and after filling it with your data, you can upload everything in one click and see them show up in the system. So we pro provide you with a template then you insert all of your ongoing customers in that file and in just one click to import them then it will show up here on on the system.